At a Glance

Follow manufacturer maintenance intervals and record all repairs in detailed maintenance logs.

Clean coolant lines quarterly and ensure no more than 5°F temperature increase between inlet-outlet.

Replace hot runner heater bands every six to 12 months and inspect thermocouples regularly.

As the year winds down, injection molds and machines deserve a thorough tune-up to ensure smooth operations in the year ahead. Neglecting maintenance can lead to costly downtime and compromised product quality. The end of the year is a critical time to restore this equipment to optimal operating condition for the new year.

Mike Stemm, business development manager for molding supplier PCS Company of Fraser, MI, emphasizes the importance of preventive and predictive maintenance over reactive approaches.

"Tooling and machines are a costly investment deserving care and respect," he said.

PCS Company, which provides solutions and products for the injection molding, mold making, and die casting industries, has more than 40 years of field experience helping molders optimize their tooling and equipment.

Stemm shared real-world insights with PlasticsToday, explaining that the automotive industry traditionally shuts down between Christmas and New Year's, providing a quiet period to focus on maintenance, tool repairs, and tool changes. This remains an ideal time to return machines and tools to optimum condition.

Preventive vs. reactive maintenance

Stemm advised following foundational guidelines to ensure end-of-year maintenance is systematic and effective:

Follow manufacturers' recommended maintenance intervals, which can be defined by calendar and/or cycle count

Record all repairs in maintenance logs, noting preventive maintenance (PM) interval changes and replacement parts required

Adopt a robust schedule of quarterly and annual maintenance periods tied to predictive cycle counts. Digital mold cycle counters can be embedded in maintenance software

While shops often plan to perform routine maintenance based on shot data, Stemm noted that execution often falls short. "That's why it often comes down to calendar timing," he said.

Key maintenance guidelines

Assessing and addressing component wear is a somewhat subjective aspect of maintenance, Stemm explained.

"When determining wear, start with a visual review and note light scoring and deep gouges," he said. "If it is seen, then you can clean, measure, and repair as needed."

Proper lubrication is another critical factor. Stemm emphasized the importance of using high-quality lubricants that meet or exceed manufacturers' recommendations and ensuring contaminants are removed prior to lubricating.

Mold maintenance checklist

To prepare molding operations for 2026, Stemm offered a detailed checklist of maintenance tasks:

Molds

Tear down and restore molds: Devote two to three days on average, or three to five days for heavily worn molds

Gating

Confirm dimensions of cold gates to prevent cavity balance degradation

Use gate inserts for easier repair and maintenance

Venting

Clean static vents and ensure dimensions are correct

Measure, inspect, and clean dynamic vents. Use ultrasonic cleaning for porous vents

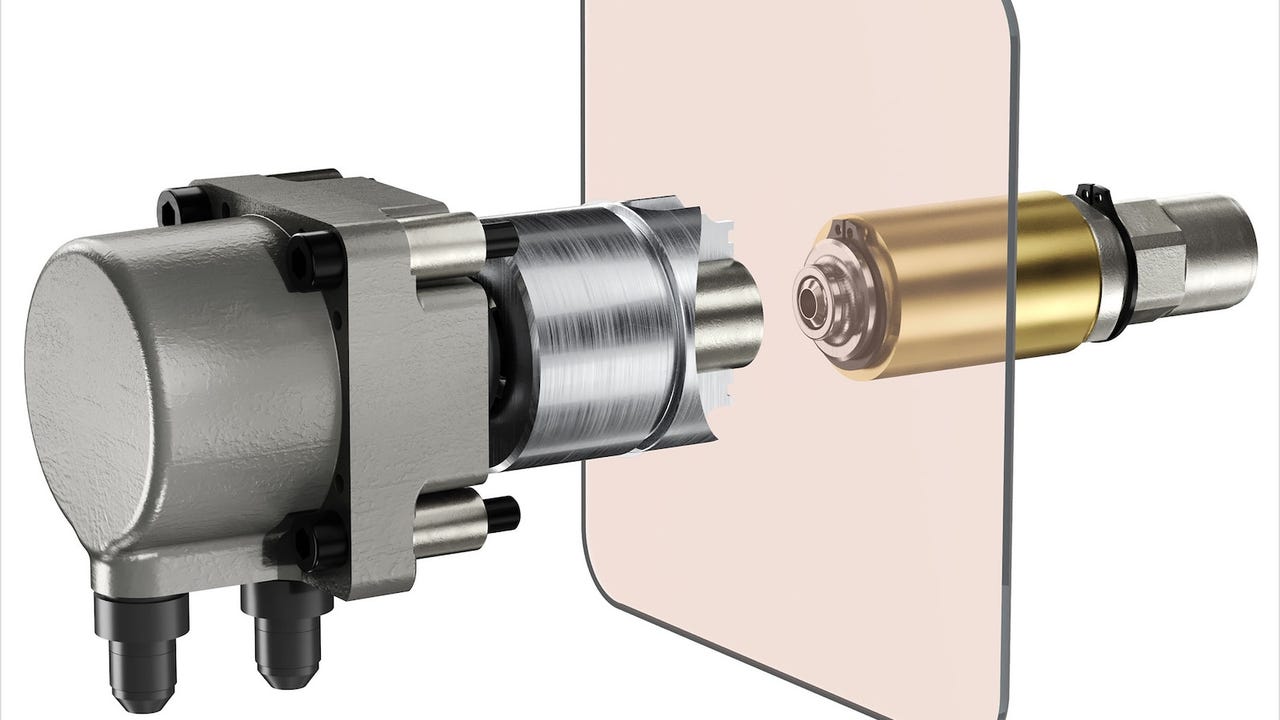

Hot runner

Inspect manifold and flow channels for leaks and wiring issues. Clean with a bake-out process above 800°F

Replace heater bands every six to 12 months and inspect thermocouples

Confirm wiring and connectors are functioning properly

Measure gate needles and tips, and repair or replace valve pins and seals as needed

Mold sensors

Recalibrate every six to 12 months, with extra sensors on hand for uninterrupted operations

Cavity & core surface finish

Clean textured surfaces with dry ice blasters and confirm gloss levels

Polish deep ribs and cores occasionally to ensure proper part ejection

Coolant circuits

Clean coolant lines and measure mold surface temperatures quarterly

Ensure no more than a 5°F increase between inlet and outlet temperatures

Ejector system

Inspect pins, springs, collapsible cores, unscrewing mechanisms, slides, and lifters for wear and replace as necessary

Date codes & inserts

Update date inserts to reflect the correct year and month

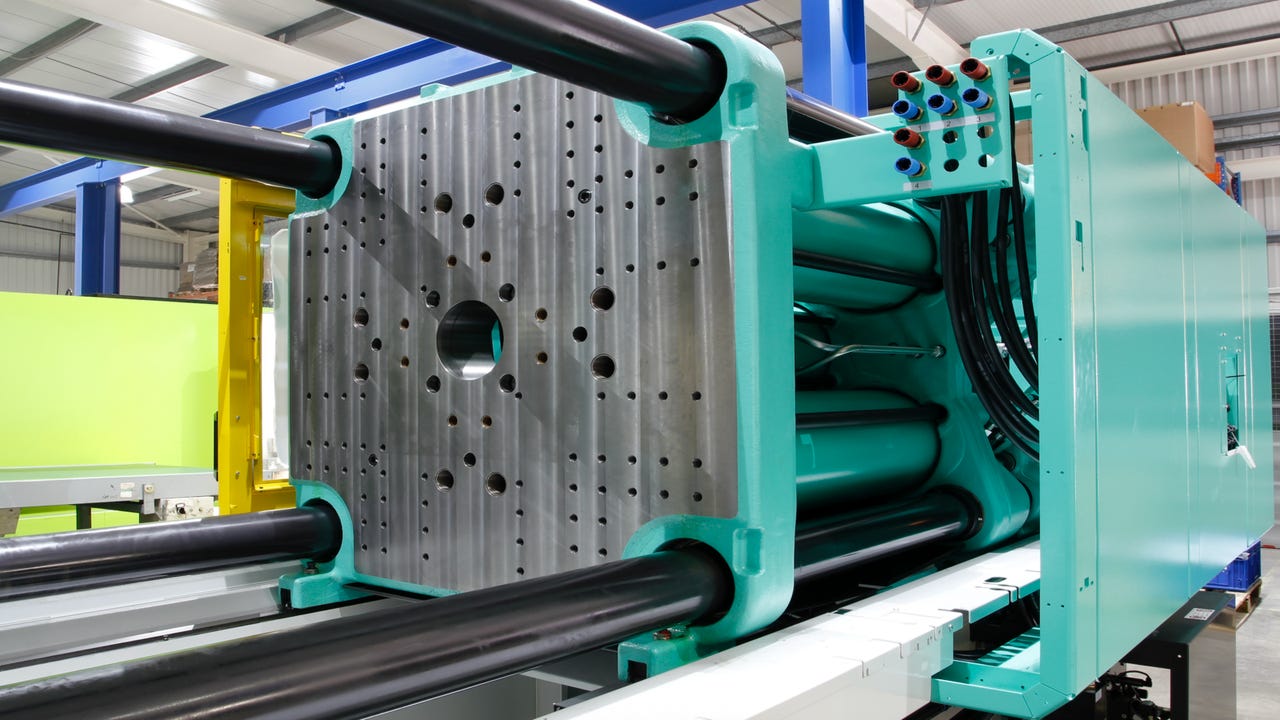

Injection machine maintenance checklist

A proper maintenance regimen for injection molding machines (IMMs) can take one to two weeks. Performing checks throughout the year shortens end-of-year repair time.

Electrical system

Inspect connection points and wires

Check integrated ancillary equipment, including robotics, mold sensors, hot runners, material hoppers, and material handling systems

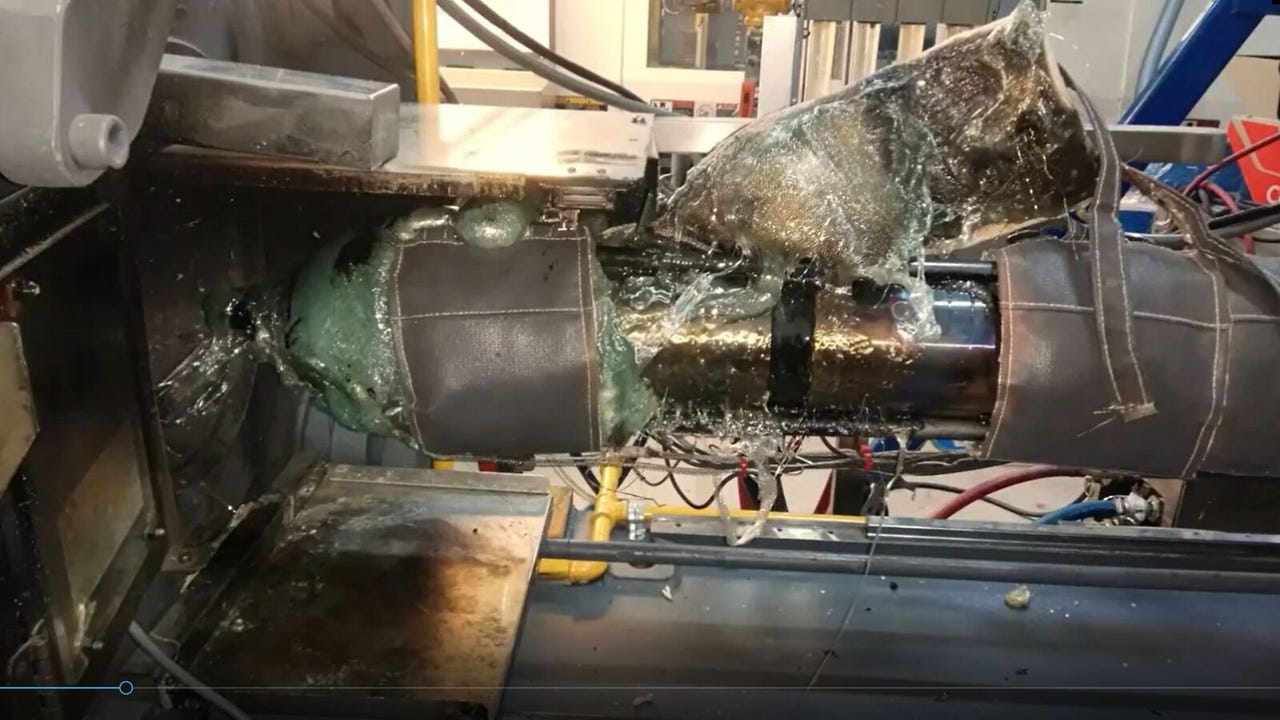

Hydraulics

Inspect for leaks at pipe joints, hoses, and couplers. Repair or replace as needed

Clean the oil tank, replace oil, and inspect filters, valves, and oil coolers

Barrels, screws & tips

Confirm barrels are within spec annually, or every six months for high-wear resins

Inspect and replace screw tips on the same schedule

Cooling

Flush and descale water lines, manifolds, heat exchangers, and chillers

Calibrate coolant flow meters

Controls

Review machine logs for incidents and anomalies

Test and repair emergency stops, safety gates, and interlocks

Calibrate pressure and temperature sensors

Educational opportunity

To streamline maintenance processes and increase efficiencies, the American Injection Molding (AIM) Institute offers specialized courses tailored to maintenance personnel, managers, and tooling engineers. Course options include:

Mold Maintenance, Troubleshooting & Repair: Structured approaches to maintenance and documentation

Hot Runner Troubleshooting & Repair: Focused on hot runner systems

Mold Maintenance Strategies: Insights into managing a busy mold repair shop

Hands-on courses: Covering mold component welding, polishing, repair, and texturing

These courses provide practical knowledge and shop skills to ensure molds and machines are ready for the challenges of 2026. Stemm noted that by following these guidelines and leveraging educational resources, companies can avoid costly downtime and ensure their equipment operates at peak performance in the year ahead.