At a Glance

The process reduces VOC emissions by 99% and CO2 emissions by 60% compared to traditional painting methods.

PUR coating technology is four times faster than conventional painting and provides self-healing, UV-stable surfaces.

The system allows for rapid color changes and integration of decorative or functional films during the molding process.

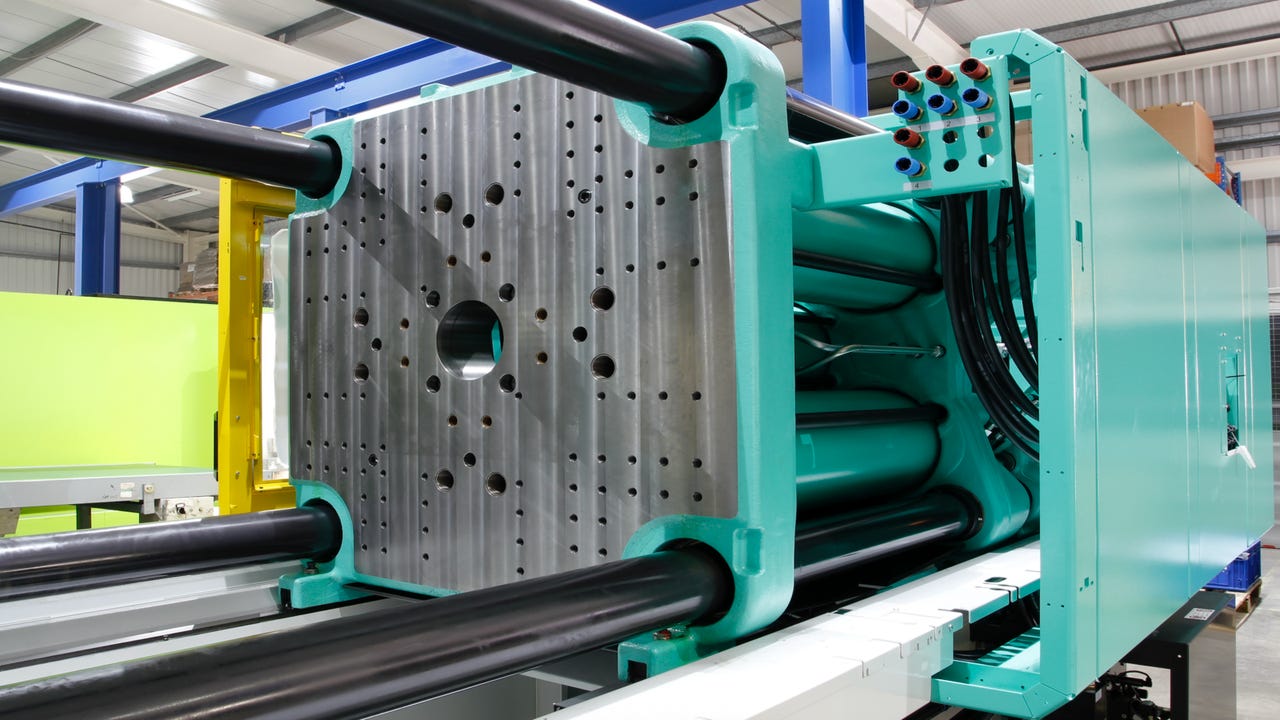

At the recent K 2025 show in Düsseldorf, Germany, Cannon and Engel introduced their joint surface coating technology process dubbed clearmelt, which reportedly revolutionizes the way automotive exterior components are manufactured and assembled. This innovative process integrates molding of thermoplastic parts and applying a polyurethane (PUR) coating into a single operation directly inside the mold. This streamlines manufacturing by eliminating the entire post-production step of painting and polishing, thereby improving efficiency and achieving cost savings.

Films can be incorporated into clearcoat parts with the Cannon/Engel process, thereby delivering aesthetic effects and functionality. Image: Stephen Moore.

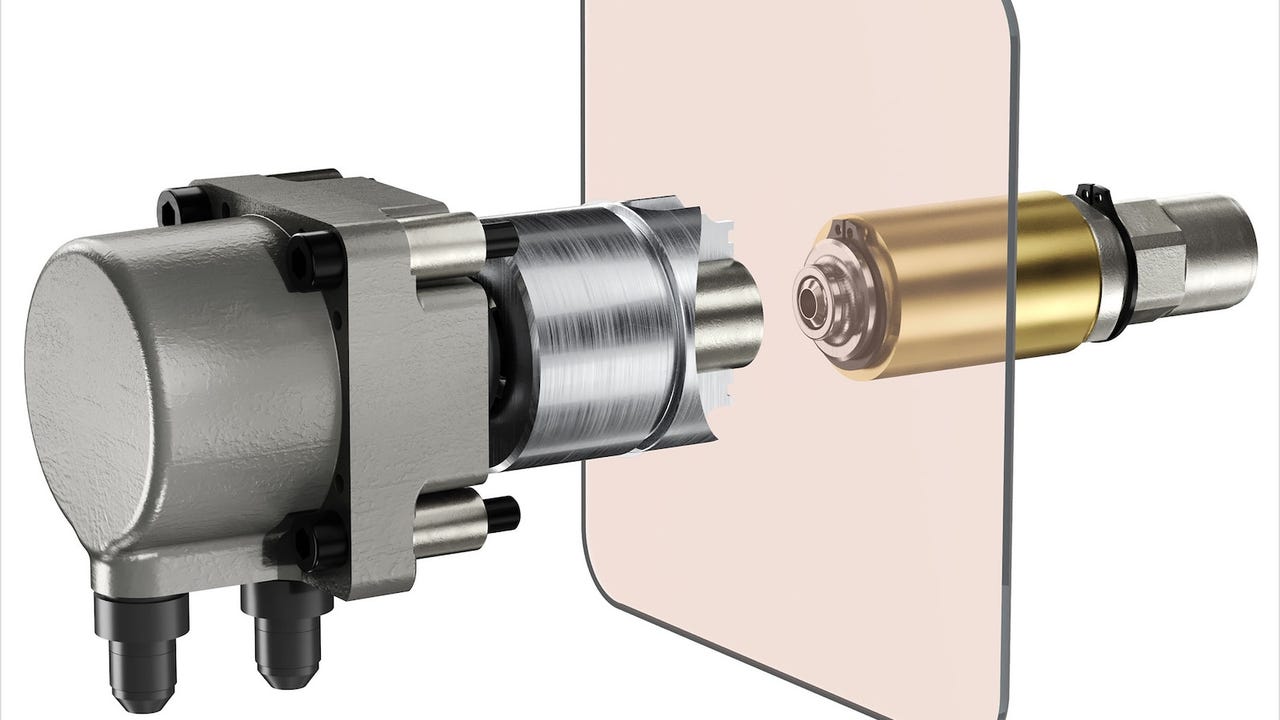

The innovative surface coating technology combines a Cannon A-Compact 10 HT PUR dosing unit, Chromafeed CCS HT color dosing unit, and LN /3 mixing head with an Engel injection molding machine. Ancillary units for automatic production, as well as software and a human-machine interface (HMI) to control both the thermoplastic molding and PUR coating processes, are also part of the cell.

“PUR surface coating has been in use for years to produce aesthetic automotive interior parts, such as dashboard trimming,” said Stefano Andreolli, sales & marketing manager, Cannon Afros. “Thanks to the evolution of chemicals and processes, this technology can now also be applied to many exterior components. The Cannon and Engel partnership aims to provide automotive and appliance manufacturers with complete production plants, whereby customers can benefit from a worldwide network of well-trained and experienced technicians and engineers in both thermoplastic and polyurethane technologies, supporting those who are new to the technology and processes in taking their first steps toward a successful and efficient production.”

In-mold integration

The Cannon PUR In-Mold-Coating (IMC) mixing heads are purposely designed to fit perfectly in the limited spaces available in the mold. The PUR mixing heads are available in a range of sizes to match any requirement in terms of flow rate and ratio, and can be provided with remote control of injectors for easy automatic adjustment through the HMI.

In-mold PUR surface coating has several advantages compared with traditional technologies for manufacturing automotive exterior parts and lighting systems. On exterior surfaces, such as front ends, hoods, door panels and roofs, it replaces traditional painting, providing a more sustainable and energy-efficient way of manufacturing and reducing volatile organic compound (VOC) emissions by 99%, and CO2 emissions by 60%. In addition, the PUR surface coating process is up to four times faster and more efficient than subsequent painting.

Self-healing, with decorative film options

Functionally, the PUR coating, typically 0.5-mm thick for exterior applications, is UV-stable and self-healing, offering reliable protection from scratches and damage. This is particularly useful for components integrating advanced driver-assistance system (ADAS) sensors such as cameras, light detection and ranging (LIDAR), and radar. The process supports both transparent and colored finishes and allows for the inclusion of decorative or functional films during molding in the coating phase. Additionally, thanks to Cannon technology, color changes can be made directly at the mixing head within minutes, minimizing downtime and increasing production agility.

In automotive lighting, the PUR surface coating replaces the hard coating process for polycarbonate, which requires several steps: Preparation and pre-treatment of polycarbonate, coating, flash-off (during which VOCs are generated), and curing. Overall, this hard coating process typically takes 10 to 15 minutes, while the PUR surface coating only takes around two minutes. When the part is released from the mold, it is nearly ready for assembly with minimal post-curing in energy-consuming ovens.

With its ability to realize Class-A surfaces, the coating of not only automotive exterior parts but also interior components can be envisaged. Speaking to PlasticsToday at the K show, Goffredo Tasca, automotive application manager at Cannon Afros highlighted decorative dashboard trim as one possible application, where functionalities such as capacitive push buttons could also be incorporated.