When it comes to molding processes in plastics manufacturing, achieving a consistent flow can sometimes feel like trying to steer a ship through rocky waters. The secret to success lies in mastering the art of melt flow balance in multi-cavity molds. A well-balanced flow not only boosts the quality of your products but also minimizes variations that can lead to production headaches. If you’re looking to enhance efficiency and ensure every part comes out just right, understanding how to manage polymer melts and temperature variations is key. Let’s explore some effective strategies to keep your molding processes smooth and efficient!

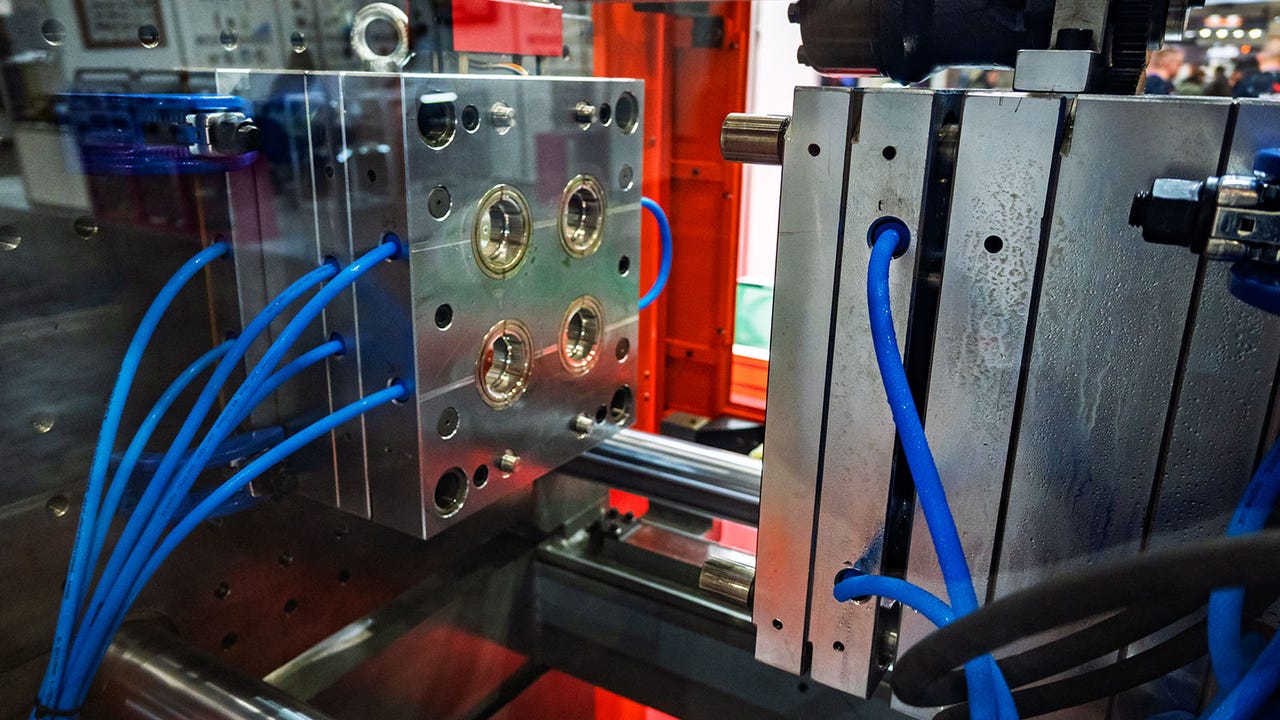

Polymer melt is categorized as a complex fluid, exhibiting behavior that can significantly change depending on shear rate and temperature. In multi-cavity molds, the melt temperature is rarely uniform, leading to challenges in maintaining flow balance among cavities. The implications of this imbalance can be severe, resulting in variegated part sizes, weights, and potentially functionalities. Figure 1 illustrates how flow imbalance manifests during the filling of a sub-runner section.

Figure 1: Unbalanced filling at the sub-runner section. Image courtesy of Moldex3D.

The importance of runner balancing

Efficient runner balancing in multi-cavity molds dramatically increases the likelihood that all cavities fill and pack simultaneously. This technique is not merely beneficial but recommended for molds intended to harbor multiple cavities. As the number of cavities increases, so does productivity; however, it is vital to ensure part consistency among each cavity to avert costly reject rates due to size or weight discrepancies.

Interestingly, flow imbalance can occur in seemingly geometrically balanced runner designs, presenting challenges even to experienced molders. Flow imbalance has been classified into two operative categories — timing control and melt quality control. To tackle these challenges effectively, one must first grasp the mechanisms behind unbalanced filling.

Understanding causes of unbalanced filling

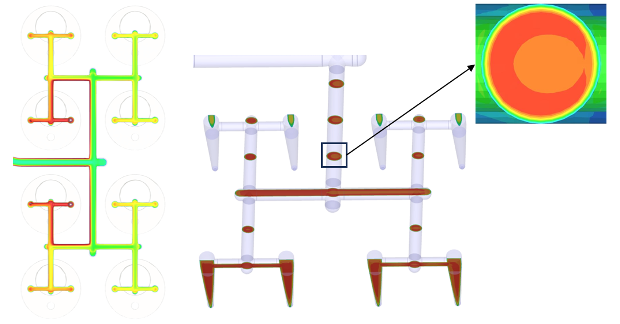

Unbalanced filling primarily arises from non-uniform melt temperature distribution within the runner system. The shear rate will show higher values near the runner walls compared to the center. This phenomenon generates friction, leading to viscous or shear heating — an increase in melt temperature can often exceed 20°C in certain conditions. Consequently, as melt splits during flow, the temperature profile becomes asymmetric, which affects flow rates — hotter melts travel faster, thereby creating imbalances. As depicted in figure 2, the temperature profile is no longer symmetric — hotter on the inside and colder on the outside. Melt, thus, travels faster on the inside due to higher temperature and this causes flow imbalance after another split. This phenomenon can be obvious for materials with a strong viscosity-temperature dependency such as PMMA.

Figure 2: Cross-sections of a runner system showing temperature distribution in the runner. Image courtesy of Moldex3D.

Strategies to mitigate these issues include extending the runner length or adjusting split locations. However, these fixes often rely on educated guessing, and any changes in material or processing conditions may require further adjustments. A more nuanced approach involves utilizing valve-gate control systems that synchronize melt entry into each cavity. Although this method yields flexible adjustments, it requires more robust investment and maintenance. Here, the power of advanced simulation software allows for insightful predictions during the mold design phase, helping to make informed decisions on runner adjustments and valve operations.

Enhancing melt quality

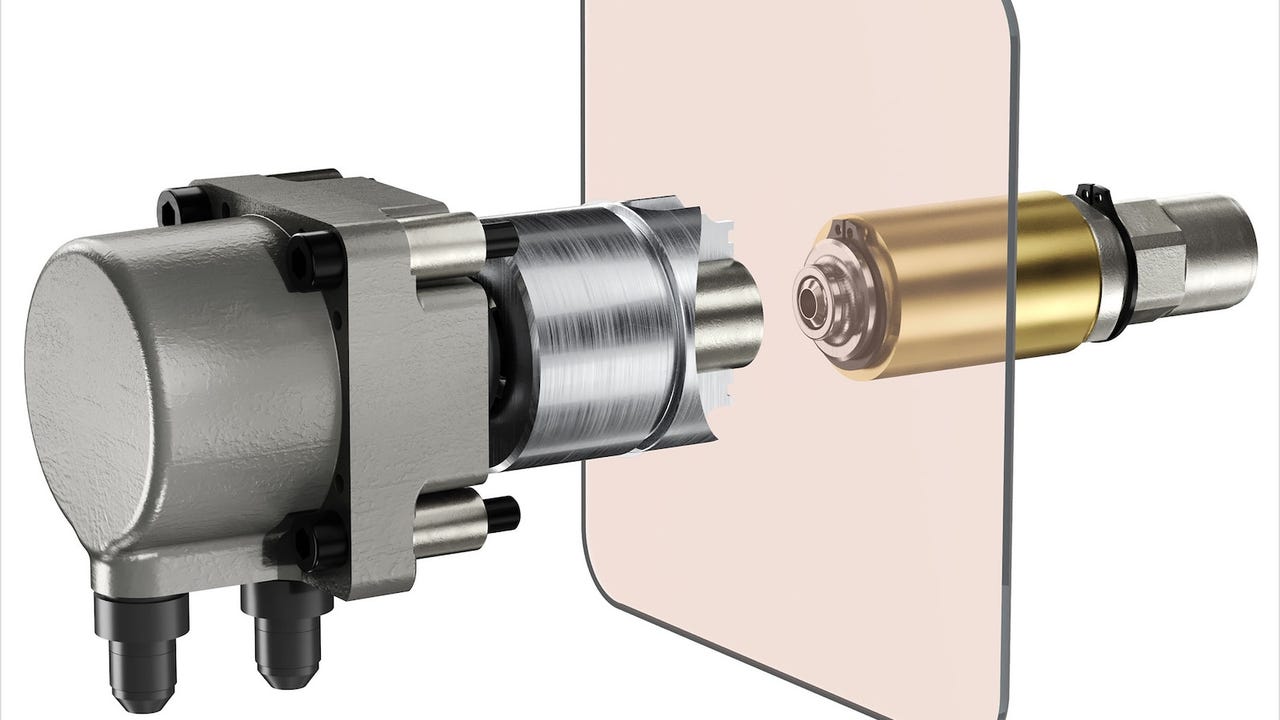

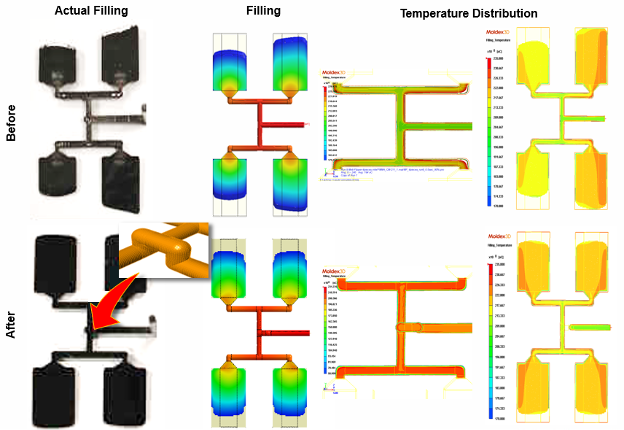

While timing control methods address flow balance, they cannot rectify temperature discrepancies in cavities that lead to variations in part shrinkage ratios. Fortunately, innovation in melt quality control techniques presents a solution. The MeltFlipper, developed by Beaumont Technologies Inc., serves as an illustrative example of employing specialized inserts in runner splits to normalize temperature distribution.

Figure 3: Before and after runner modification. Image courtesy of Moldex3D.

Equally significant is the role of advanced hot-runner systems. These designs, such as a single hot runner featuring multiple side gates, mitigate runner length and enhance uniform temperature distribution down to the gate area. As such, they help eliminate both cavity-to-cavity and shot-to-shot variation, while precise simulation data remain essential to validate the feasibility of these designs.

Conclusions and a call to action

The significance of flow balance in multi-cavity molding cannot be overstated. It directly influences product quality and operational efficiency. Advanced strategies, such as runner balancing, valve-gate control, and innovative melt quality techniques are pivotal in addressing the complexities associated with multi-cavity molds.

As the industry continues to evolve, having a reliable partner that understands these challenges is paramount. Simulation software stands ready to support professionals facing flow balance issues or seeking guidance in process optimization. So, don't let your production process head adrift — set sail toward success by achieving flow balance or selecting the right techniques for your needs!