At a Glance

The machine produces a two-cavity 5-L pail with handle and in-mold labeling in just 5.9 seconds.

Ultra-fast injection speeds up to 450 mm/s are enabled by twin low-inertia electric motors.

Stork's STIC software ensures process consistency by correcting for material variations in real time.

Netherlands-based Stork IMM will showcase its new all-electric injection molding machine at K 2025, running Oct. 8 to 15 in Düsseldorf, Germany.

The packaging machinery manufacturer will debut the next-generation All-Electric 6600-3550 with 2K in hall 13 at stand 72.

The machine delivers industry-leading performance capabilities for thin-wall food packaging and industrial paint bucket production. The company noted that, unlike current market offerings, it combines 2K heavy-duty performance with all-electric precision, providing manufacturers a high-performance alternative for high-output packaging production.

Live demonstration

At K 2025, the Stork IMM 6600-3550 will produce a two-cavity 5-L pail with handle and in-mold labeling (IML) in just 5.9 seconds. This live showcase demonstrates the machine's ability to combine speed, precision, and energy efficiency in heavy-duty packaging applications.

"This machine extension satisfies growing customer demand for high-performance injection molding machines that meet the productivity demands of the packaging market," said Tony Mekenkamp, sales director for Stork IMM.

Advanced engineering

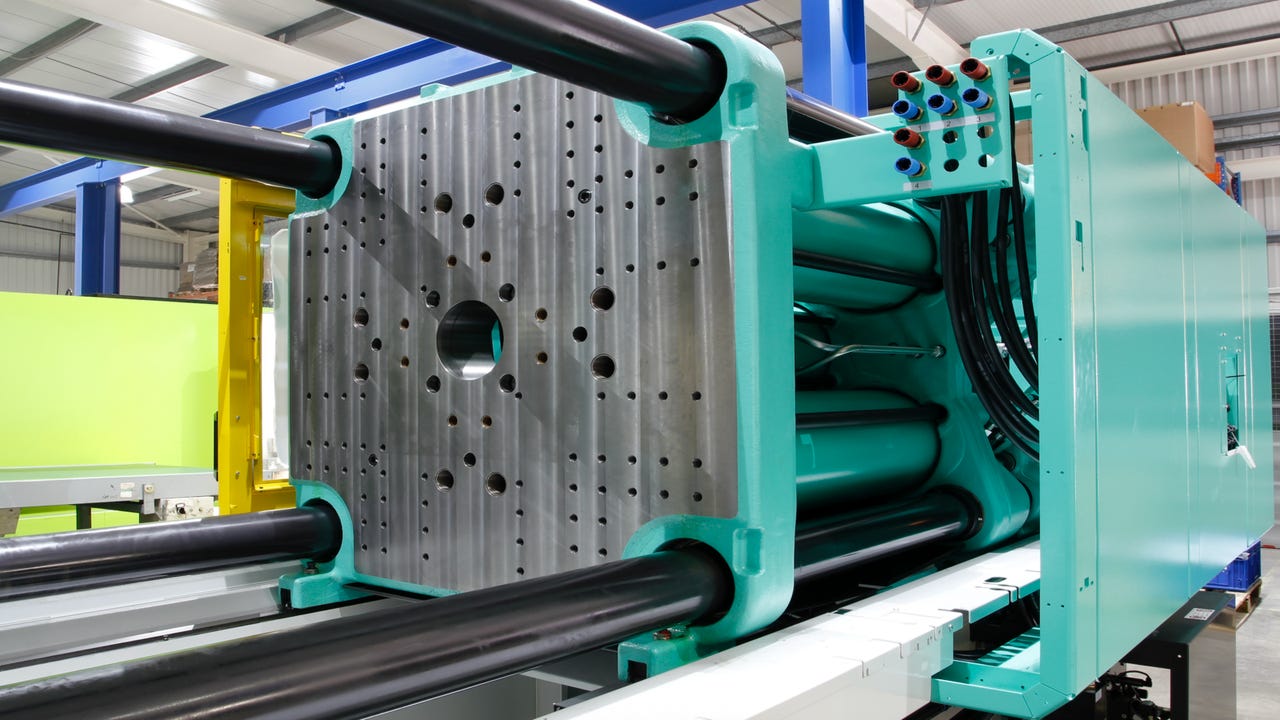

Stork said its all-electric range sets new performance standards with mold filling capabilities through ultrafast injection acceleration, achieving exceptional flow-length over wall-thickness ratios. The machine's improved platen stiffness, linear guiding under the movable platen, and clamped toggle pins result in extended mold life, higher part quality, and increased productivity in demanding applications.

For pail production with handles, Stork IMM has proven that ultrafast acceleration capabilities of the all-electric system provide major benefits for both product quality and output. Dynamics, inertia, and clamp position repeatability are critical factors in repeatable production of high-quality products, resulting in higher productivity with lower material consumption.

Machine specifications

The Stork IMM all-electric range targets flower pots, pails, food packaging, and other thin-walled products. With clamping forces ranging from 2,500 to 9,000 kN, these machines provide:

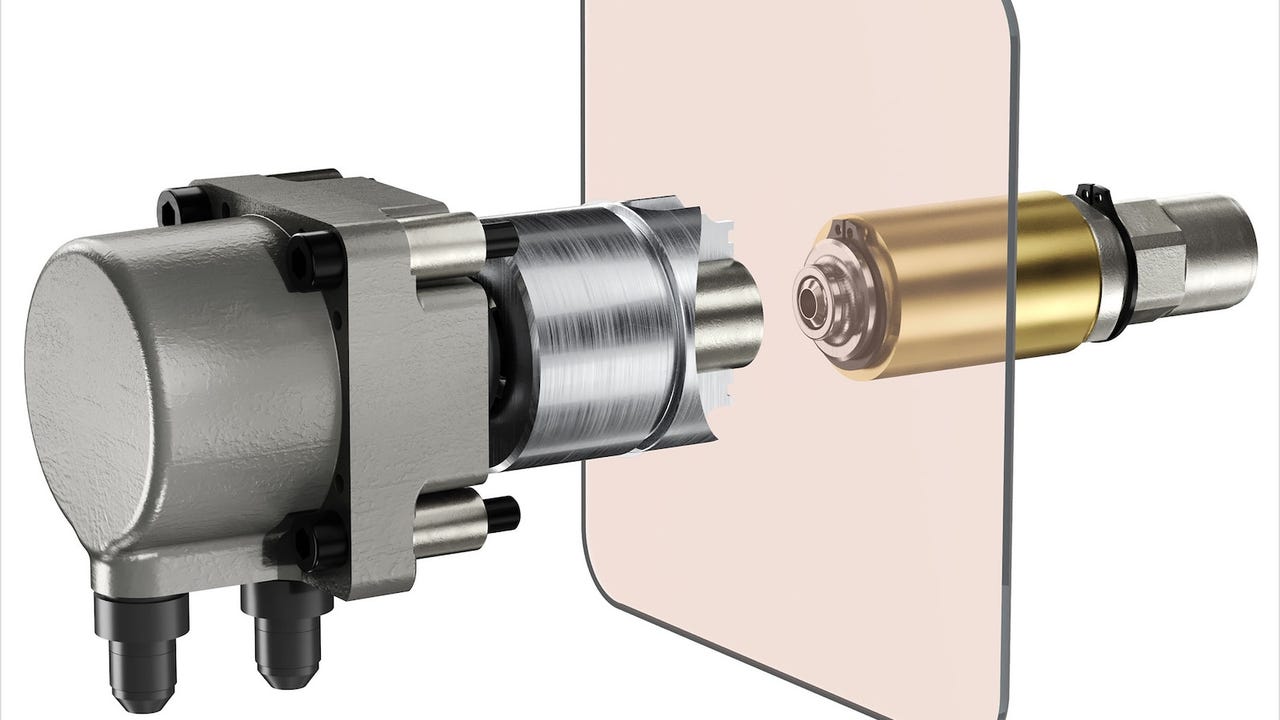

Ultra-fast injection speeds up to 450 mm/s enabled by twin low-inertia electric motors

Improved platen stiffness and stability for maximum product quality and longer mold lifetime in high-cavity molds

Rack-and-pinion design for greater energy efficiency and long-term durability

Heavy-duty reliability to run 24/7 at short cycle times with low energy consumption

The machine's energy efficiency, lower carbon footprint, and reduced noise levels make it ideal for modern plants focused on performance and environmental responsibility.

Advanced process control technology

The Stork Injection Control (STIC) software ensures process consistency by correcting for material variations in real time. STIC guarantees shot-to-shot accuracy, making it particularly effective when processing regrind or recycled materials.

Stork IMM will also highlight its 3300-1450 hybrid unit at K 2025, part of the proven Stork IMM Full Hybrid Range featuring electric clamping, electric dosing, and hydraulic injection. The company said this machine will demonstrate high-output production of an eight-cavity silicone cartridge with ultrafast injection speed capability, improved platen stiffness, linear guiding under the movable platen, and clamped toggle pins for extended mold life.

The combination of electrical and hydraulic drives results in low energy consumption to meet industry sustainability and cost-efficiency demands.

Market applications

Stork's high-speed injection molding machinery offers solutions for food-grade, thin-wall packaging made of polyolefins (PE and PP). According to the company, the machines deliver maximum performance at minimum operational costs with lower material costs, reduced energy consumption, and shorter cycle times. Key applications include closures, tubs, containers, cups, flower pots, and paint pails and buckets.

Founded in 1968, Stork IMM specializes in designing and manufacturing high-speed injection molding machines for the plastics processing industry. The company employs approximately 150 people at facilities in Hengelo, Netherlands, and Meinerzhagen, Germany. Stork IMM maintains local sales and service partners worldwide to support its customers.