Editor’s note: This is a corollary to an article by the same author on instances when a hydraulic press might be the best option — “Hydraulic vs. Electric Injection Molding Machines: When Energy Efficiency Isn't Everything.”

How often at trade shows, in company adverts, or on LinkedIn have you seen some injection molding machine supplier explain why their all-electric press can save you thousands on your energy bill?

The reason why manufacturers and salespeople do this is because the first thing that comes to mind for most people when considering the advantages of all-electric machines is energy efficiency. In fact, if you ask most machine suppliers and industry experts to list the benefits of all-electric injection molding machines in order of priority, the list will probably look something like this:

Energy efficiency

Precision & repeatability

Lower operating costs

Cleaner operation

Quieter operation

Faster setup & adjustments

Reduced cooling needs

Higher operational time & reliability

Environmental benefits

Improved cycle time

Compact design

This emphasis on energy savings distracts from the real productivity benefits: All-electric molding machines have so much more to offer than just a reduction in electricity costs.

Higher operational time and reliability should be number one on any list of priorities, closely followed by precision and repeatability and lower operating costs. This is where the real benefits, cost savings, and additional profits will be realized. Once you have calculated the benefits from those three items, the reduction in the cost of energy compared with a hydraulic machine is really just the cherry on top.

To emphasize my point about energy savings, let’s look at a theoretical worst-case scenario in terms of a simple payback calculation between an all-electric and servo-hydraulic machine. The example will clearly show that energy-saving benefits on their own may not justify the higher initial purchase price of an all-electric injection molding machine over a five-year period.

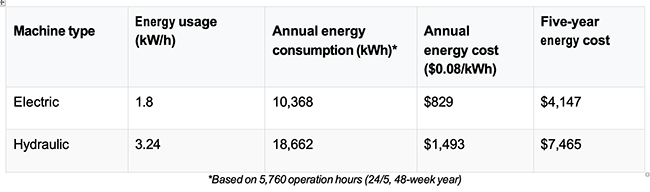

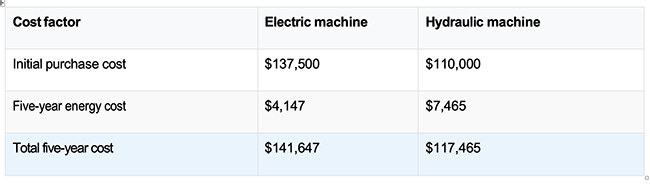

Energy cost estimate for a 1000-kN injection molding machine

Cost-benefit analysis: 1000-kN injection molding machine (energy only)

Please note: All figures used are for the purpose of clarification and are a simplification designed to show potential (worst-case) differentials and are not meant to be an accurate representation of real-life figures or costs.

Based only on machine energy costs, the higher purchase price of an all-electric machine may not be recovered through energy savings alone over a reasonable period (five years). In this example, an energy cost saving of just under $3,318 will be realized over five years using the best performing all-electric machine compared to a basic servo-hydraulic machine. If we assume the energy usage and annual consumption rates remain constant, it would take 41 years and five months for the initial machine cost plus energy cost to be at parity, with each machine’s total cost being $171,834.

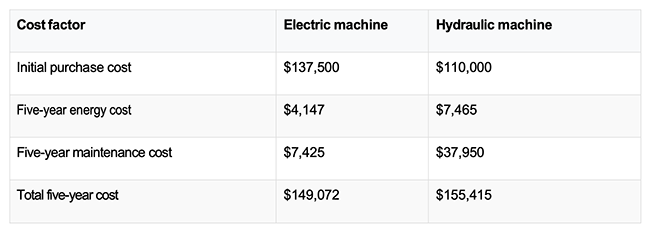

However, this is not the whole picture. We can assume that the annual cost of spare parts for an all-electric machine will be considerably less than for a servo-hydraulic machine (based on around 1.08% of initial purchase cost per annum for electric compared with 6.9% of the initial purchase cost for servo hydraulic). Over a five-year period, the best performing all-electric machine may cost you around $7,500 in spare parts and consumables while the servo-hydraulic machine could set you back around $38,000 over the same period.

Cost-benefit analysis: 1000-kN machine five-year total cost (including maintenance)

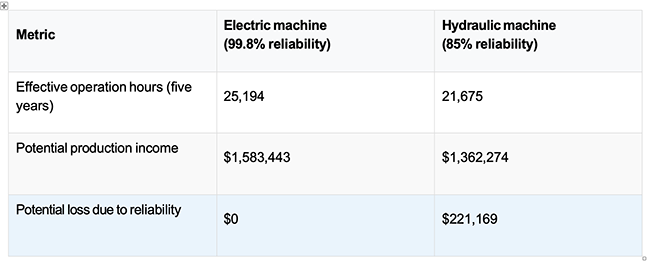

In addition, all-electric machines are known to be much more reliable than servo-hydraulic machines, partially because they have fewer moving parts and feature more accurate mechanical movements thanks to the enhanced control of electric drives. This will lead to electric machines being more reliable and, therefore, available for more production hours.

Here’s one example.

The assumptions are as follows:

Factory efficiency rate of 85% (preventive maintenance, mold change, machine cleaning, etc.)

Machine efficiency rates (unplanned stoppages)

All electric @ 98.8%

Servo hydraulic @ 85%

Factory operational hours

50 weeks

24/5 hours = 120 hours per week

Total available hours = 5,100 per annum

1,000-kN hourly rate @ $62.85

Please note: Hourly rates, both nationally and at state levels, vary widely, so this is a combined average rate based on available information and is not intended to be representative of any actual implemented rates.

Scenario 1: Reliability impact on operational costs 1000-kN machine with hourly rate of $62.85

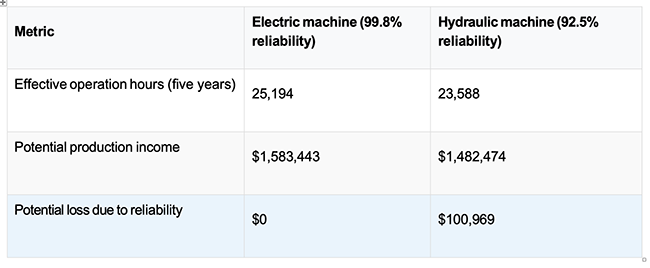

Even if you give both the servo-hydraulic machine much higher reliability ratings, the hydraulic machine could still potentially lose you over $100,000 over a five-year period.

Scenario 2: Reliability impact on operational costs of 1000-kN machine at hourly rate of $62.85

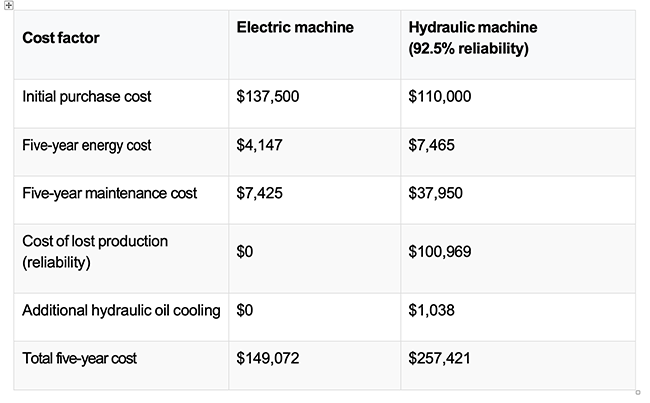

If you add up the additional cost of spare parts and the potential cost due to lost manufacturing hours and add in the cost of cooling the hydraulic oil over five years, the cost of ownership strongly favors the all-electric option, even when applying the higher reliability rates above for the hydraulic machine.

Complete cost-benefit analysis: Five-year total cost (all factors included)

An all-electric machine could have paid for its initial purchase cost by the end of year one through operational savings alone. And this calculation excludes many of the other additional benefits:

Precision and repeatability, improved cycle time for specific applications;

faster setup and adjustments (servo motors reach optimal operation instantaneously).

Beyond the energy savings hype

While energy efficiency remains a genuine benefit of all-electric machines, it should never be the primary justification for purchasing one. The compelling case lies in operational reliability, precision consistency, and reduced total cost of ownership.

When building your business case, calculate the full operational impact, including uptime, maintenance costs, part quality, and production flexibility. These factors typically dwarf energy savings in their financial impact.

Whether you're considering a premium all-electric machine or an entry-level model, evaluate the complete value proposition. Your electricity bill will thank you, but your production schedule and profit margins will thank you even more.

Final note

The example above was designed to be a worst case scenario to emphasize the many potential benefits that all-electric machines can offer. Under real world conditions, however, the actual payback time of an all-electric machine may be somewhere between two to four years or more. Depending on available budgets, job production life span, and general molding requirements, a servo hydraulic machine might be the preferred option, as not every molder or application has the luxury of a five-year return on investment schedule.