At a Glance

All-electric machines use less energy per cycle than hydraulic machines regardless of size, even above 800 tons.

Hydraulic machines excel at thick-walled parts and complex applications requiring bursts of power and pressure.

Financial constraints and contract risks can make lower-cost hydraulic machines the preferred business choice.

Regardless of machine size, all-electric machines will use less energy per cycle than hydraulic machines on the same part. Research indicates that this holds true even on larger machines above 800 tons.

Above 1,000 tons, most manufacturers do not offer all-electric models. This is not because hydraulic machines are inherently more efficient at greater tonnages but because servo drives and mechanical parts become disproportionately bigger, costlier, and harder to engineer as the clamp size grows.

You might conclude that the only reason to choose a hydraulic machine below 1000 tons would be cost, but there are many scenarios where a hydraulic machine might be the preferred option.

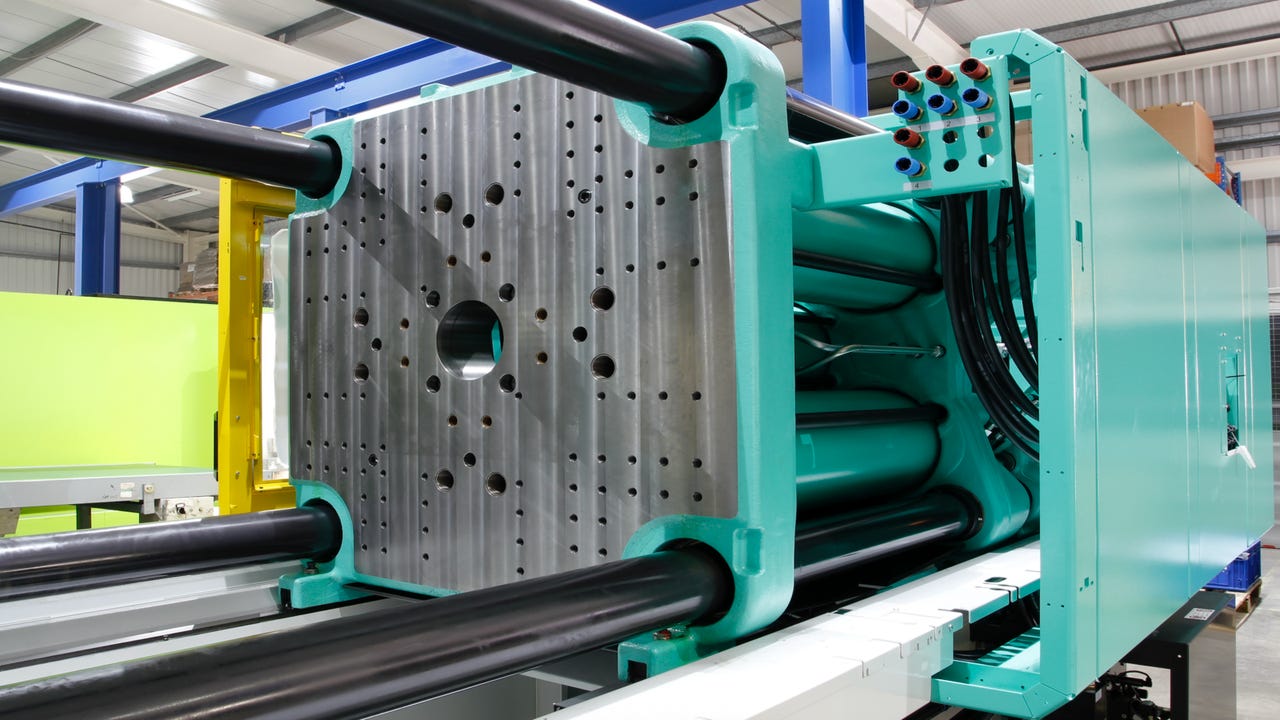

For instance, when molding thick-walled parts or large thin-walled components, or when inserts and complex cores are involved, hydraulic presses have an edge. Hydraulic systems deliver bursts of power and clamp pressure that electric machines struggle to match. Accumulators provide rapid energy surges for fast filling applications, while hydraulic clamps can securely hold heavy inserts. In these types of applications, the trade-off in energy efficiency is small compared to performance and reliability gains.

So, there are applications where a servo hydraulic or hybrid technology machine may be the preferred choice. There can also be financial, commercial, and personal reasons for choosing a hydraulic or hybrid machine over an all-electric solution. Here are some examples.

Minimizing contractual financial exposure

A custom injection molder considering a two-year contract to produce small appliance covers must account for a no-fault termination clause at the 12-month mark, necessitating cost recovery within the first year. To mitigate the risk of unrecovered costs from early termination, the molder can front-load margins by structuring pricing to cover tooling, machinery, and setup expenses upfront. Opting for cost-effective, high-quality capital equipment, such as a servo hydraulic machine with a three-year parts and labor warranty, ensures operational reliability while minimizing financial exposure if the contract ends early, especially since specialized tooling and machinery may have limited alternative uses.

Budgeting for a replacement machine

Let’s say you need an additional or replacement machine, but short-term financial constraints restrict your budget. In this situation, a lower-cost hydraulic machine with a parts and labor warranty could be the most practical option, allowing you to meet production requirements while minimizing impact on long-term budgets and asset management. This approach works for asset management because the machine can be written off quickly, reducing long-term depreciation commitments and limiting the risk of carrying under-utilized equipment.

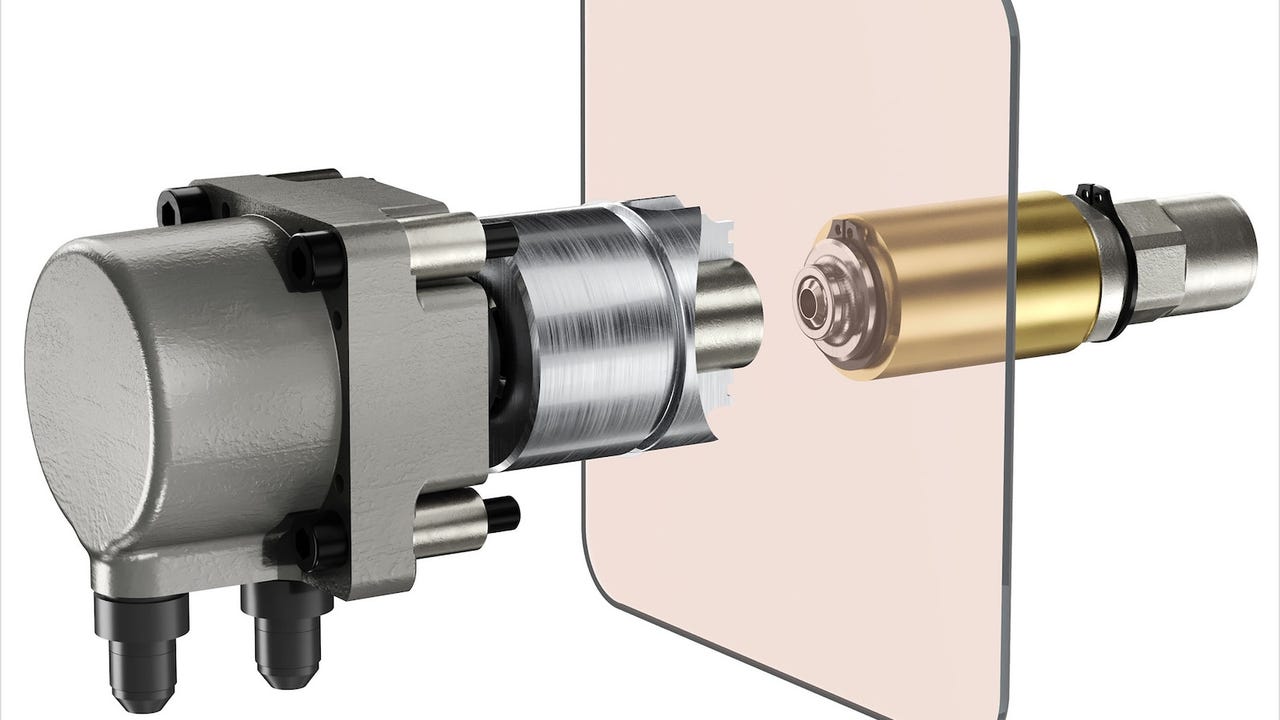

Analog vs. digital

This point is somewhat subjective but still worth consideration. All-electric machines are, by design, mechanically simple: They are primarily built around straightforward drive systems with the complexity residing in control software, servo motors, and sensors. They are, in essence, highly digital pieces of equipment. For engineers with a background in fluid power, mechanical assemblies, linkages, and drives, there can be a certain reassurance in the way a hydraulic injection molding machine operates. In a world that is increasingly digital, there is sometimes real value in having an analog system you can fully understand and physically get to grips with.

In the end, choosing between hydraulic and all-electric machines is rarely clear-cut.

While all-electric machines may dominate efficiency metrics and represent the technological future, hydraulic machines continue to earn their place through application-specific advantages, commercial pragmatism, and operational familiarity. The decision isn't always about choosing the most advanced technology — much of it depends on the part, process, financial strategy, risk management, and operator preferences.

Ultimately, selecting the right machine means balancing technical demands with cost considerations and the practical realities of your operation. And there are certainly cases when an electric injection molding machine will be your preferred option. We look at some of those scenarios in "The Case for All-electric Presses."