At a Glance

Material uses carboxymethyl cellulose and safe crosslinking agents for rapid ocean decomposition.

Plastic incorporates FDA-approved choline chloride plasticizer to achieve flexibility from rigid to elastic.

Team adds polyethylene-imine guanidinium ions creating reversible salt bridges for controlled breakdown.

A team of researchers in Japan has unveiled a groundbreaking plant-based plastic that could revolutionize the fight against microplastic pollution. Made from carboxymethyl cellulose (CMC), a biodegradable wood-pulp derivative, and a safe crosslinking agent, this innovative material is strong, flexible, and decomposes rapidly in natural environments, including salt water, without leaving harmful microplastics behind.

The research team, led by Takuzo Aida, a researcher at the Riken Center for Emergent Matter Science (CEMS) in Japan, published their findings in the Journal of the American Chemical Society.

"Nature produces about one trillion tons of cellulose every year," Aida explained. "From this abundant natural substance, we have created a flexible yet tough plastic material that safely decomposes in the ocean. This technology will help protect the Earth from plastic pollution."

Tackling the microplastic crisis

Microplastics — tiny fragments of plastic less than five millimeters in size — have become a pervasive contaminant, infiltrating ecosystems, wildlife, and even human tissue. While biodegradable plastics have been marketed as a solution, many fail to degrade effectively in marine environments, exacerbating the problem.

Aida's team has taken a significant step forward by creating a plastic that not only decomposes quickly but also matches the strength and versatility of conventional petroleum-based plastics.

A practical & scalable solution

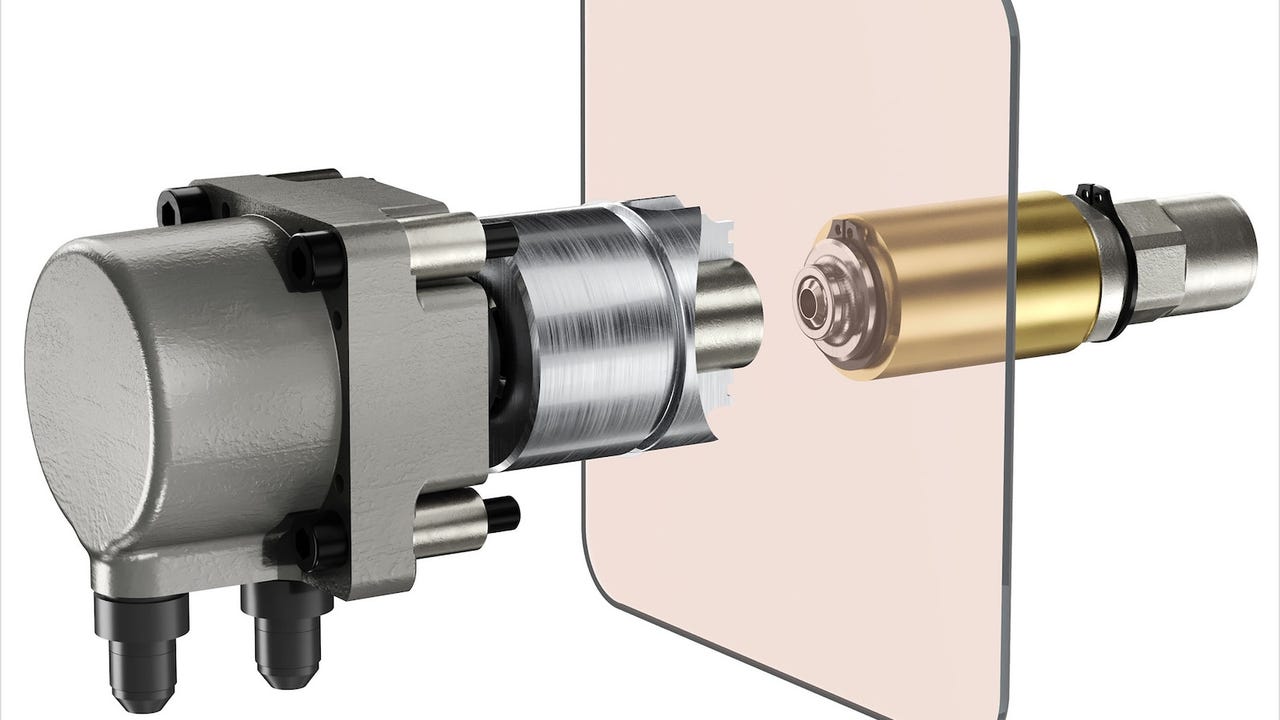

Last year, Aida's team introduced a supramolecular plastic that dissolved in salt water within hours, leaving no microplastics behind. However, its limited practicality for large-scale manufacturing spurred further innovation. The new plastic, dubbed carboxymethyl cellulose supramolecular plastic (CMCSP), builds on this earlier work by incorporating Food and Drug Administration-approved, biodegradable ingredients.

The key breakthrough came from combining carboxymethyl cellulose with positively charged polyethylene-imine guanidinium ions, forming a cross-linked network held together by reversible "salt bridges." The researchers said these bonds break down in salt water, allowing the plastic to decompose safely.

To address initial brittleness, the team added choline chloride, an FDA-approved food additive, as a plasticizer. Aida said the adjustment allowed them to fine-tune the material's flexibility, creating a range of textures from hard and glass-like to elastic and stretchable.

Scalable, sustainable & ready for real-world use

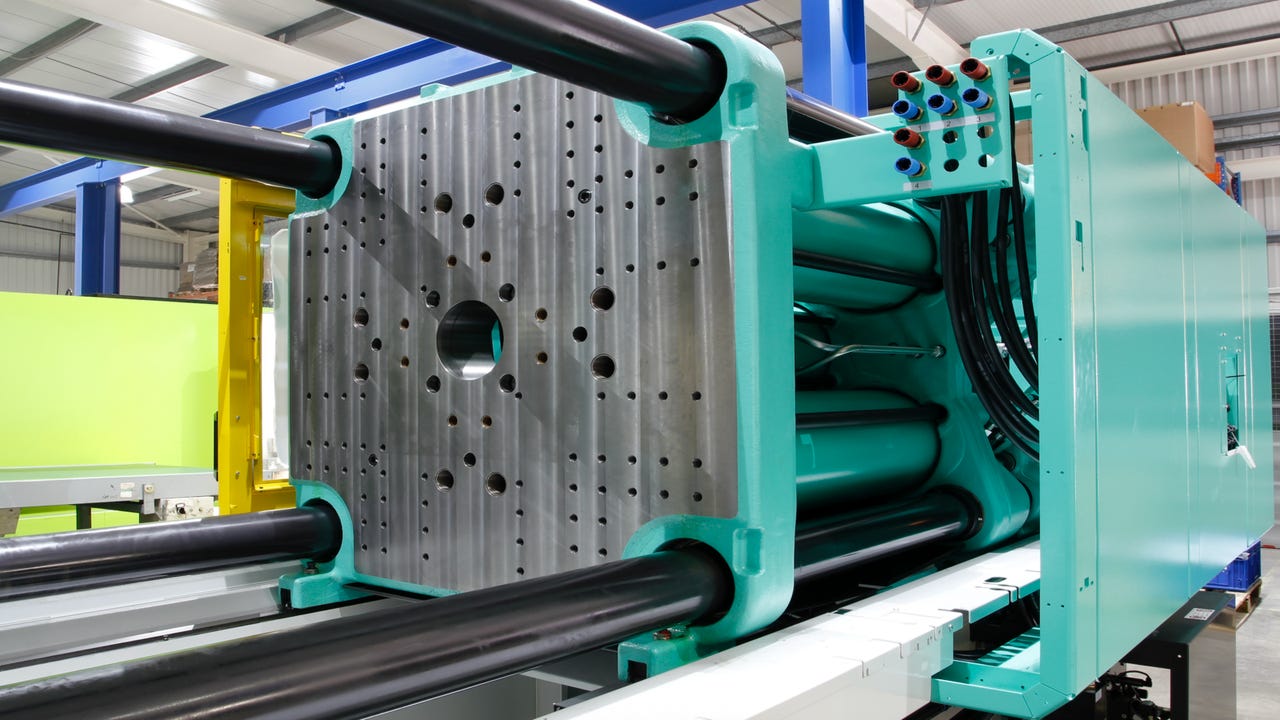

The new plastic's versatility extends to its applications. It can be made into thin films as strong as conventional plastics, with a thickness of just 0.07 mm. Importantly, the material retains its transparency, processability, and recyclability, making it suitable for a wide range of uses, including packaging, medical devices, and consumer goods.

Aida noted that while the team's earlier study focused on conceptual development, the current research demonstrates a more practical and scalable design.

With its practical design and use of inexpensive, widely available ingredients, CMCSP is poised to make a significant impact in reducing plastic waste and protecting marine ecosystems. The researchers said this innovation represents a critical step toward a cleaner, more sustainable future.