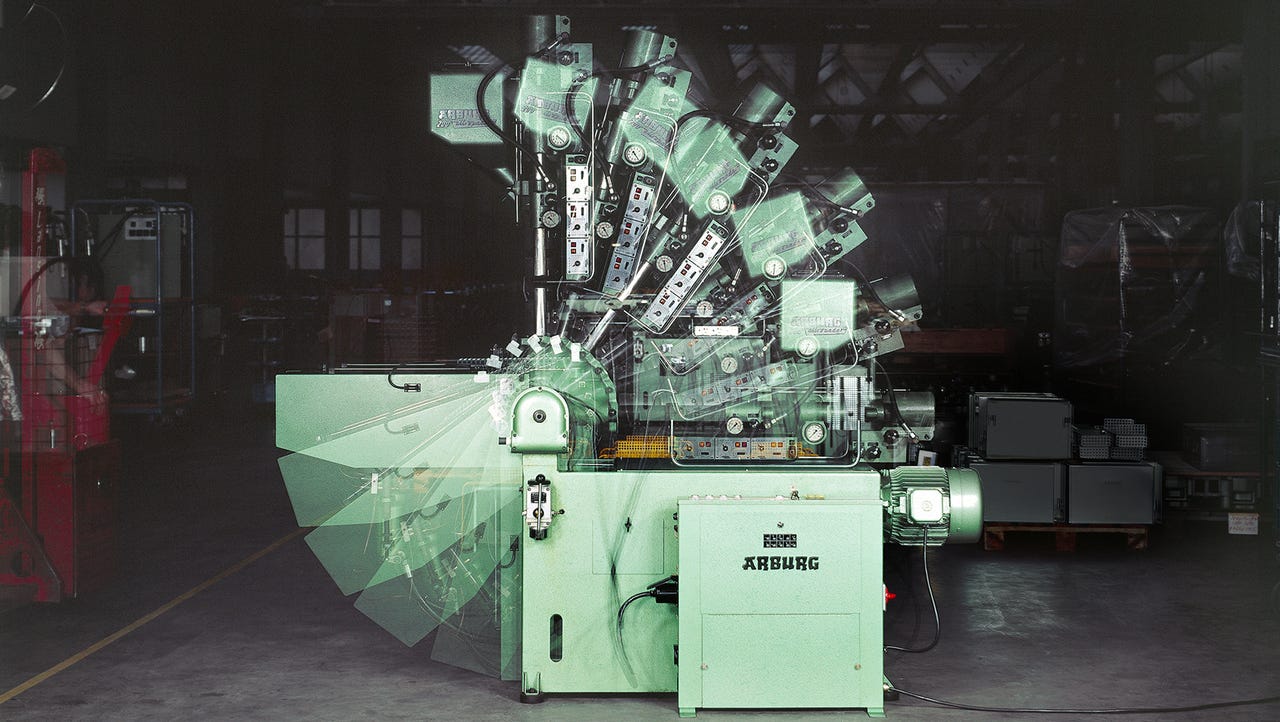

Arburg was founded in 1923 by Arthur Hehl, who produced surgical instruments in the cellar of his home. In 1954, his son Karl developed a small injection molding machine for the production of plastic components. But it wasn’t until 1961, when the company based in Lossburg, a small town nestled in Germany’s Black Forest, took on a truly international dimension with the invention of the Allrounder molding machine. The Allrounder principle would revolutionize injection molding, and the technology continues to be refined to this day.

A simple idea

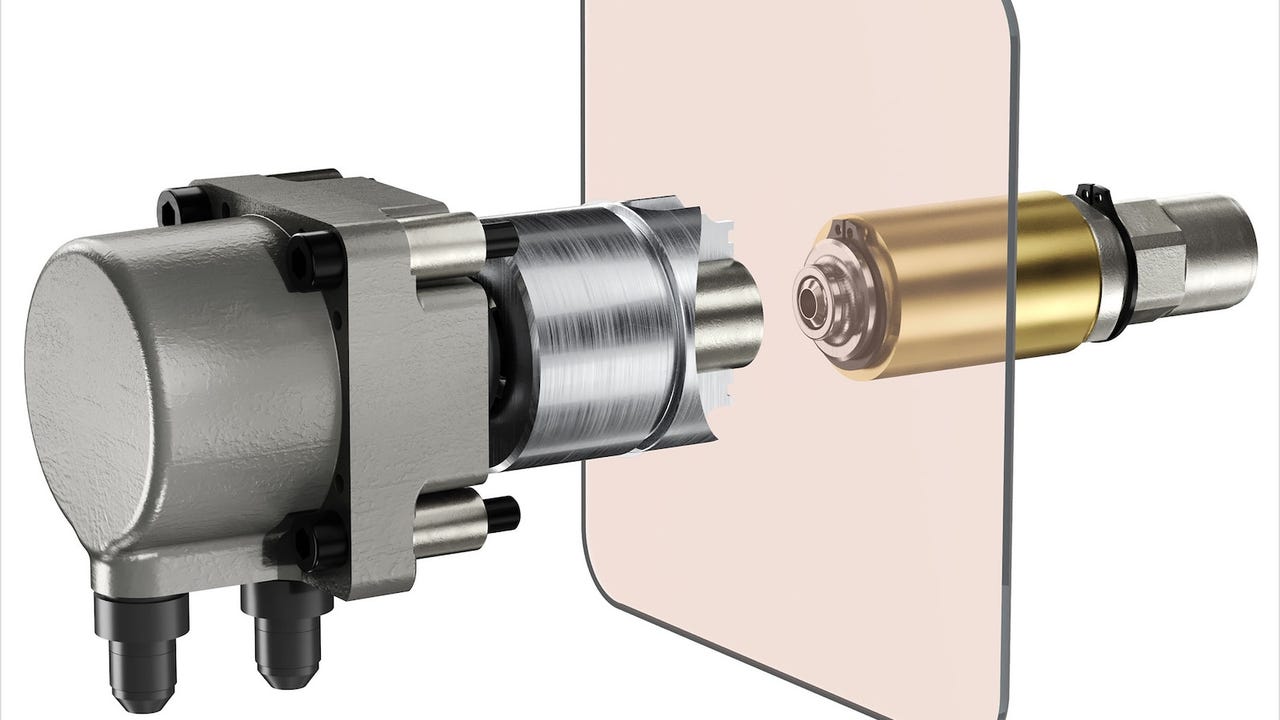

The groundbreaking design is articulated around a relatively simple idea, said Arburg — a modular injection molding machine that was flexible enough to be used for a variety of different tasks.To achieve this, the company explained, the clamping unit merely needs to be made pivotable using a hinge mechanism, and the injection unit needs to be positioned upright using a repositioning mechanism. The Allrounder 200 was the world’s first injection molding machine to feature pivoting clamping and interchangeable injection units. This departure from a conventional rigid construction made extremely flexible working possible. One machine could work in seven different positions, replacing an entire machine fleet, according to Arburg. The modular machine enabled a diverse range of possible applications: It could encapsulate inserts and process elastomers as well as thermosets.

A telephone dial was one of the first two-color injection molded parts produced on an Allrounder press. Image courtesy of Arburg.

This technology also paved the way for multi-component injection molding, added Arburg. Combining a horizontal and vertical injection unit to inject two different materials into a staged mold that rotated mechanically made multi-component injection molding possible in 1962. One of the first two-color injection molded parts produced in this manner was a telephone dial plate.

Command and control

Starting in 1975, Arburg used its world-first standard microprocessor controller with a programmed command structure in the Allrounder H. The next step was a machine with graphical user interfaces. Machine parameter settings could be entered, checked, and, for the first time, continuously monitored and stored. The development ultimately led to the Selogica controller that was introduced to the market in 1993.

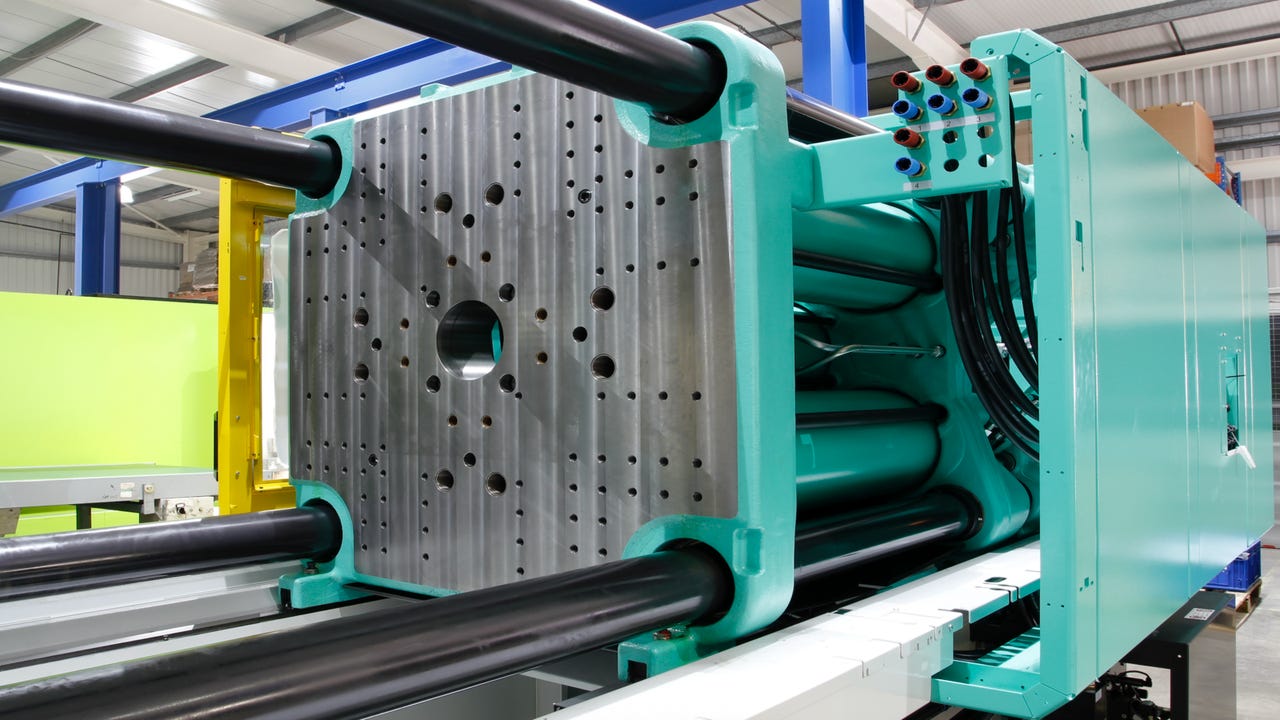

Innovations at K 2025

Over the years, the family-owned company has built on this foundation in pursuit of continued innovation, and it will show its latest advances in injection molding technology at K 2025 in Düsseldorf, Germany. Notably, Arburg will introduce a vertical Allrounder with a clamping force of 1,000 kN at the event running from Oct. 8 to 15. Making its world debut, the press features a small footprint, energy efficiency and a new control system at an attractive price. At the Arburg stand in hall 13, the machine will be molding a part designed for mobility applications.

Arburg also will host a pavilion in front of hall 16 dedicated to the circular economy, a focal point of which will be an automated system that converts recycled fishing nets into model dolphins.