At a Glance

Pickleball participation surged 223% since 2021, reaching 20 million players.

Balls use different manufacturing processes for beginner versus advanced play.

Sustainability innovations include new compostable balls breaking down in 100 days.

The rapidly growing sport of pickleball represents a significant opportunity for plastics processors, with specialized ball manufacturing techniques driving product performance in this expanding market segment.

National Pickleball Day, celebrated on August 8, recognizes the sport and its growing popularity across the United States. Equipment for the sport is manufactured by plastics processors nationwide, including the specialized balls used in gameplay.

Despite being invented in the 1960s, pickleball has emerged as the fastest-growing sport in the United States, according to the Sports and Fitness Industry Association (SFIA). The organization reports that participation has grown by more than 223% since 2021. The number of players in the US rose to nearly 20 million in 2024, with millions of newcomers embracing the sport each year.

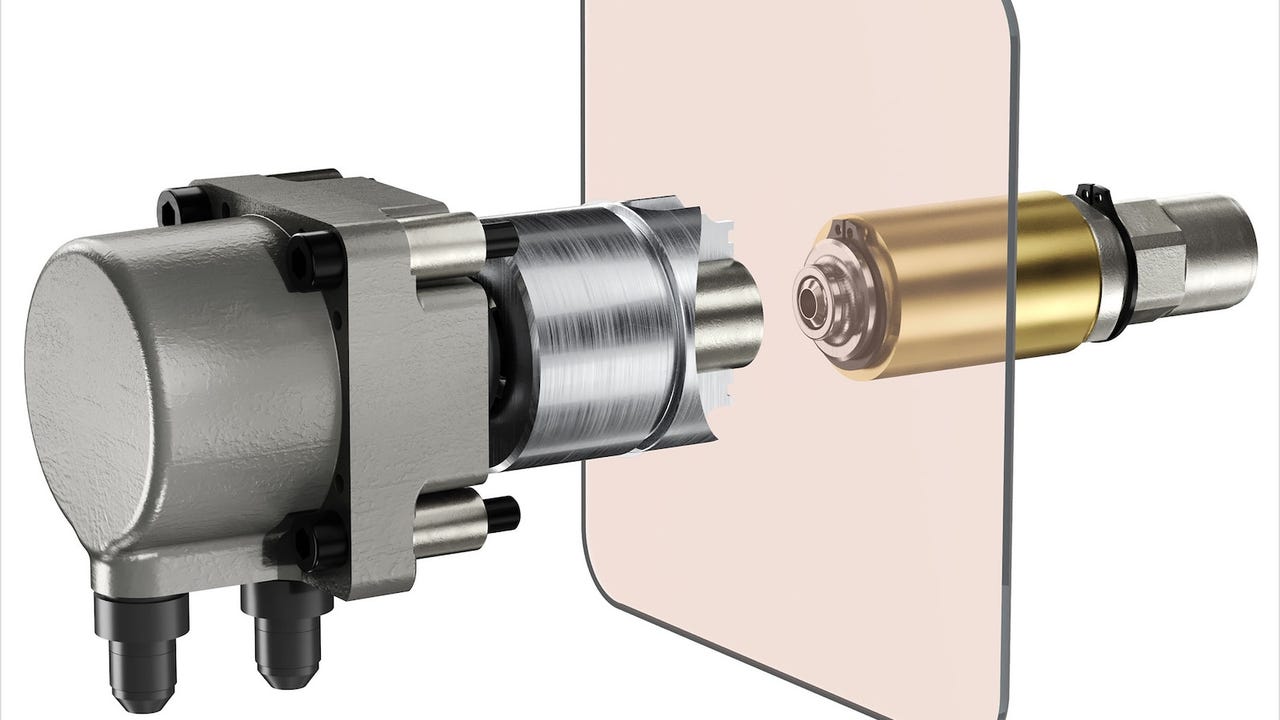

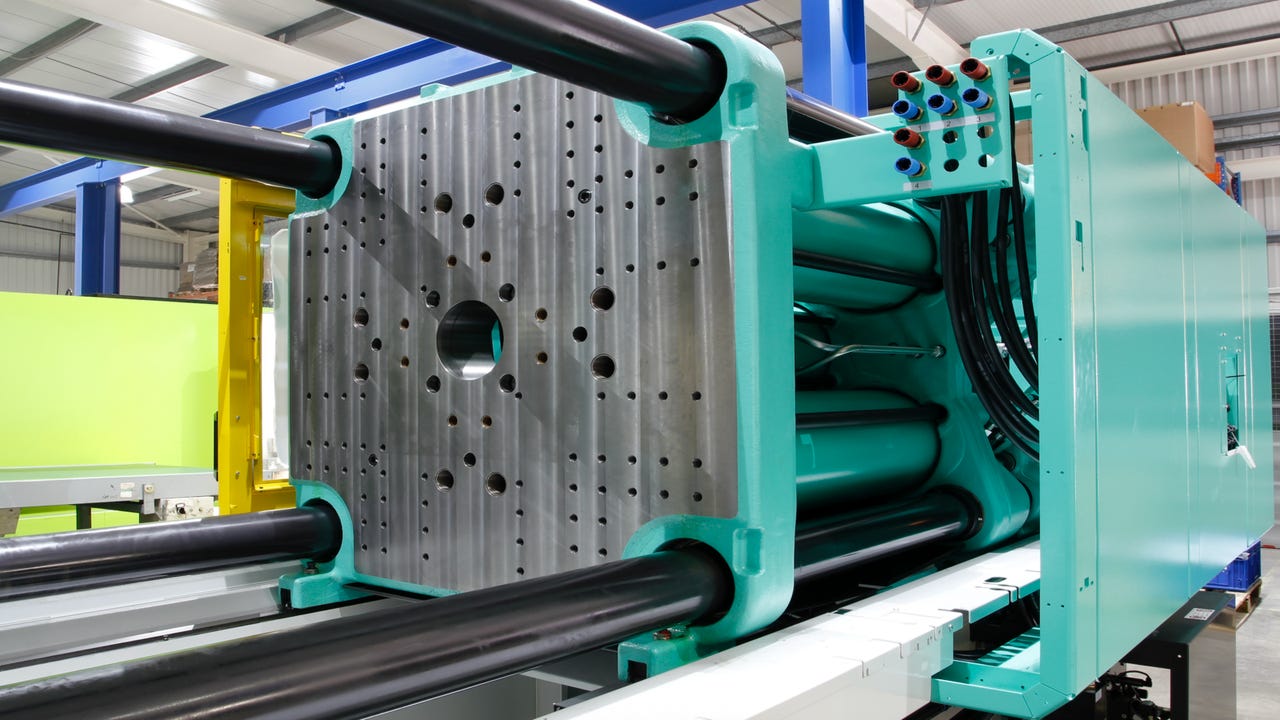

Pickleballs are typically made from durable, lightweight polymers like polyethylene (PE) or polypropylene (PP), using specific formulations tailored to their intended use environment. The balls are manufactured through either injection molding or rotomolding processes.

Riley Burgess, vice president of Equipment Compliance at USA Pickleball, the governing body for the sport, explains that the two different manufacturing methods appeal to different segments of players.

"Generally speaking, the rotational molded ball produces a faster ball, which is preferred by more advanced players," he said. "Injection molded balls usually are more durable and slightly slower, which is better for beginner players."

Burgess noted that USAP-sanctioned tournaments require balls that are approved through the USAP ball testing protocols.

Different formulations of resin are used depending on whether the ball is designed for indoor or outdoor play. "The material is not necessarily considered at the player or tournament organizer level — brands can make a ball as they please," he explained. "It just needs to pass the USAP testing."

Leading the pack

Wilson Sporting Goods was ahead of the craze and began to ideate its first pickleball design in 2018. It partnered with Dow Chemical to develop the company's first pickleball, the TRU 32.

"Dow offers extensive material options and strong R&D capabilities, meaning we get the opportunity to try out several solutions to make our racket sports gear even better," said Chloe Lee, an advanced materials engineer at Wilson Sporting Goods. "This sort of testing flexibility allows our teams to streamline innovation. It helped us successfully cross-develop player-preferred pickleballs and tennis balls."

Their collaboration also resulted in the second-generation TRU 32 Pro, which debuted in late 2024. Wilson describes the injection-molded Tru 32 Pro pickleballs as being “designed for advanced competitive play, with a pattern of 32 holes delivering consistent flight and bounce traits.”

Pickleballs are typically made from durable, lightweight polymers like polyethylene or polypropylene, using specific formulations tailored to their intended use environment. Vicvaz/iStock via Getty Images.

Material selection

Angel Morales is chief development officer for Professional Pickleball Partners, aka Pro-Pickle. Pro-Pickle acquired Core Athletics, a manufacturer of pickleball equipment based in Leawood, KS, six months ago. He explained that while specific formulations are proprietary to their clients, different densities of PE are commonly used in pickleball production.

Morales said that rotomolding has typically been used for outdoor balls (40 holes) due to its more robust and "seamless" construction. Injection molding is most used on indoor balls (fewer number of holes – 26).

"It is important to clarify that outdoor/indoor refers to the surface where the sport is played, not necessarily if the court is covered or not," he said. "Indoor surface is typically wood, as you would find in a gymnasium or basketball court."

Indoor pickleballs primarily incorporate PE resins, selected for their flexibility and controlled rebound characteristics. Morales said these softer formulations provide predictable bounce on smooth indoor surfaces while maintaining structural integrity.

Outdoor variants rely on more rigid PP compounds engineered to withstand UV exposure, temperature fluctuations, and abrasion from rough playing surfaces. This material differentiation directly impacts flight dynamics, according to Morales, with outdoor balls typically exhibiting faster speeds despite their more challenging playing conditions.

Manufacturing processes

Two primary production methods dominate the pickleball manufacturing landscape, each yielding distinct performance attributes. Injection molding remains the industry standard for high-volume production.

"Injection molding is a better option as you can control a lot of potential issues from arising," Morales said. "You can produce a considerably larger number of balls in the same amount of time it takes to make roto."

The resulting two halves are subsequently bonded, creating a characteristic seam. This cost-effective approach produces balls with higher bounce characteristics preferred by recreational players.

Rotational molding represents the premium manufacturing alternative. Post-production drilling creates the hole pattern.

"Rotomolding is a lot more complex as you have a lot of things that will cause unwanted variance in hardness, wall thickness, bounce, durability, and other factors," Morales said. "Cost is usually higher as well, but, up more recently, this was the only way to make a truly high-performance pickleball."

These seamless balls command higher price points but deliver superior aerodynamic performance and extended durability valued in competitive play.

At Core, both injection molding and rotomolding processes are utilized for ball production.

"This is something that we have been working on for quite some time and we look forward to being the first to make 100% high-performance balls in the US for our clients," Morales explained. "We are using state-of-the-art molding, with tolerance levels unheard of in the industry, and incorporating robotics to replace the highly labor-intensive manufacturing process of rotomolding."

Morales said Pro-Pickle is using what he called a "reverse approach."

Over the years, Morales said the company has produced millions of toys for the restaurant industry.

“We are applying what we have learned into the production of pickleballs to make it not only more affordable but also of better quality,” he said.

Precision engineering of hole configurations

The hole pattern engineering represents a critical design element affecting ball performance. Indoor pickleball balls feature approximately 26 larger-diameter holes, strategically positioned to reduce drag and enhance control in consistent indoor environments.

Outdoor variants incorporate approximately 40 smaller-diameter holes specifically engineered to minimize wind interference and maintain flight stability. This precision drilling or molding process requires tight manufacturing tolerances to ensure consistent performance across production batches.

Color formulation

Colorant selection extends beyond mere aesthetics to address functional requirements. High-visibility pigments — particularly yellows and lime greens — dominate outdoor ball production, formulated to maintain visibility across variable lighting conditions while resisting UV degradation.

Indoor applications frequently utilize orange or white colorants optimized for contrast against typical court surfaces. These specialized color formulations must maintain consistent dispersion throughout the polymer matrix while meeting durability requirements.

Sustainability initiatives

As the sport continues to grow globally, environmental considerations are becoming increasingly important.

USAP’s Burgess said sustainability is a consideration for the sport.

“This topic has become more top of mind recently, and we will be looking into some of the recent products that have hit the market,” he said.

When it comes to sustainability, Morales said this can be a challenge, with hundreds of millions of pickleball balls being sold annually worldwide.

"In late 2024, we began producing the very first injection-molded, 100% compostable ball on the market," he said.

Made with a patented blend of wheat straw and rice husk, Pro-Pickle's Compost-a-Ball breaks down in around 100 days in landfills, leaving less waste behind while improving soil health.

Morales said the ball will be the official ball of the Pickleball World Cup in October/November, where more than 64 countries will be competing at The Fort pickleball club in Fort Lauderdale, FL.

The company will introduce its Gen 3 version in 2026.

Quality control parameters

According to Burgess, all paddles and balls are subject to market testing, and are expected to pass USAP tests throughout the life of the product under normal use.

Official tournament-approved pickleballs must meet strict dimensional and performance specifications, including diameter (2.874 to 2.972 inches), weight (0.78 to 0.935 ounces), and bounce characteristics.

Morales pointed out that pickleball manufacturers enact quality control measures and testing protocols to ensure consistent wall thickness, weight distribution, and bounce characteristics across production runs.

"We check hardness, roundness, wall thickness, and nine other QC data points on every single batch of balls," he explained. "Our batches cycle through a two-hour process, which means we are performing these checks four times a day."

Performing a pre-production, intervention, and post-production protocol is critical to ensure consistency, according to Morales.

"Our balls are used at the highest levels of competition, so it is critical that they perform accordingly, but also that we can guarantee our customers that the ball has met all the criteria set during design and development," he said. "We work with third-party labs to test, and with certification agencies that confirm the above."

As a result, sophisticated quality control systems are required throughout the manufacturing process. Processors must maintain tight tolerances while balancing material costs, production efficiency, and performance characteristics to remain competitive in this specialized market segment.

Market growth

With pickleball participation expanding at double-digit rates annually, polymer processors are developing advanced formulations and manufacturing techniques to enhance ball performance while extending product lifespan.

When it comes to scaling production to meet growing demand, Morales said it requires an increase in machinery and tooling.

"Due to the increase in demand, we have decided to control production in the US, rather than have captive factories overseas," he said. "We will be running productions simultaneously, as we will still be supplying Asian and European markets."

Moreover, Morales said Pro-Pickle is in negotiation with some partners overseas where it can place its machinery to reduce distribution and logistics time in regional markets.

"The biggest factor in scaling is incorporating robotics," he concluded. "While it will be expensive at the beginning, the increase in production will pay for itself down the road."

This rapidly evolving market segment presents significant opportunities for materials suppliers and processors capable of delivering consistent, high-performance products to meet growing consumer demand.