Custom injection molding involves the process of injecting materials that are molten by heat into a molding tool to produce parts. The materials and produced parts are generally plastic, and are used in many product industries. It is a core manufacturing technology for the mass-production of identical parts.

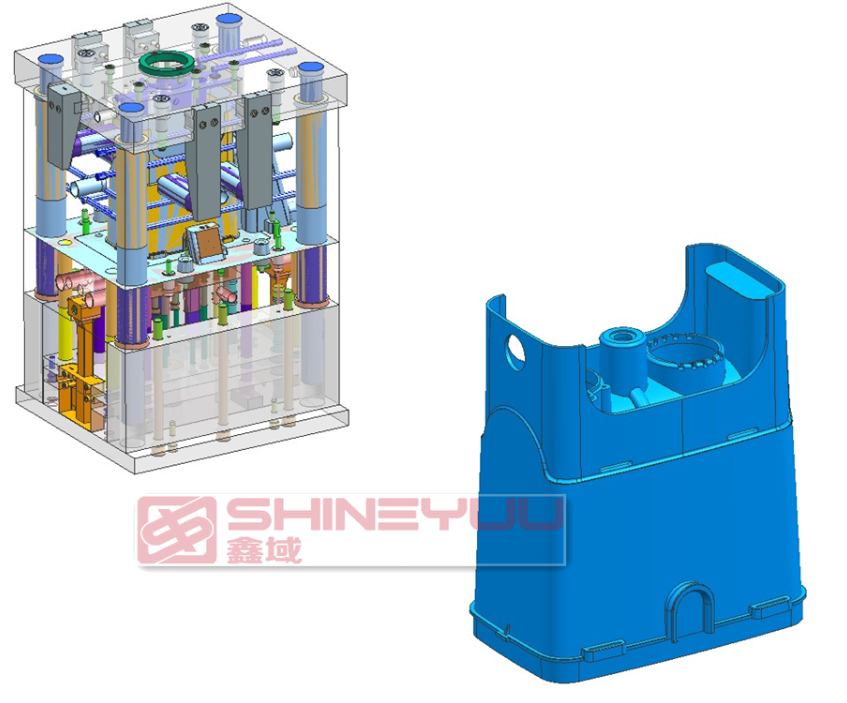

For example, a custom injection mold which can be seen in the image below, is a specifically made part usually made from steel, aluminium or other metal alloys and is a critical part of the custom injection molding process.

A custom plastic injection molding definition would be similar, with custom plastic injection molding, these molds can produce thousands of plastic parts over the course of its lifetime.

The key understanding of custom injection molding is just how exact custom injection molding specifications need to be. It’s vital that an injection molder understands and aligns with the needs of your product, since parts that are used in certain fields – like medical or military – vary greatly when compared to foods containers or toys. This demands attention from professionals who are truly well versed in complex designs and compliance from a custom plastic injection molding company must be strictly adhered to.

What Is The Custom Injection Molding Process?

When it comes to injection molding custom, there is generally three significant steps in the process: they involve product design, mold design and the manufacturing process.

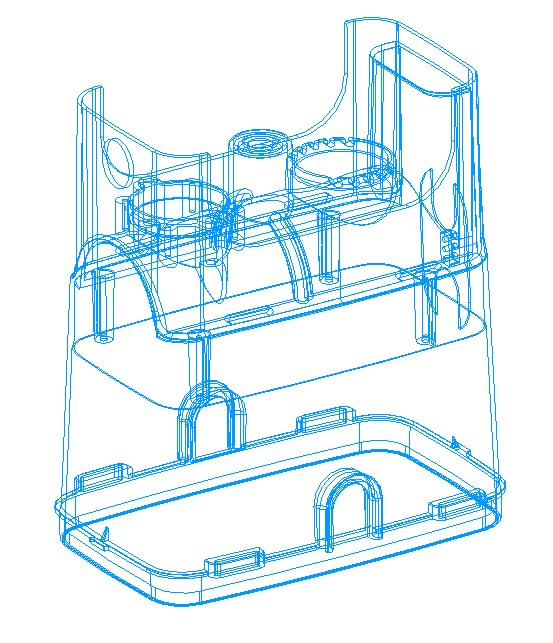

The design process also happens to be one of the most important processes, since it is a great early opportunity to prevent any expensive mistakes from happening later. Function, assembly, manufacturability and aesthetics all play an important key role in determining the product design process and the right design is one that accomplishes your objectives to a satisfactory level. The product design stage is usually accomplished with a CAD software, which stands for computer aided design. In order to engineer custom injection molding, skilled engineers will brainstorm, design and improve a variety of issues surrounding the particular product at this stage.

See below for an image of a product during its design process on CAD software:

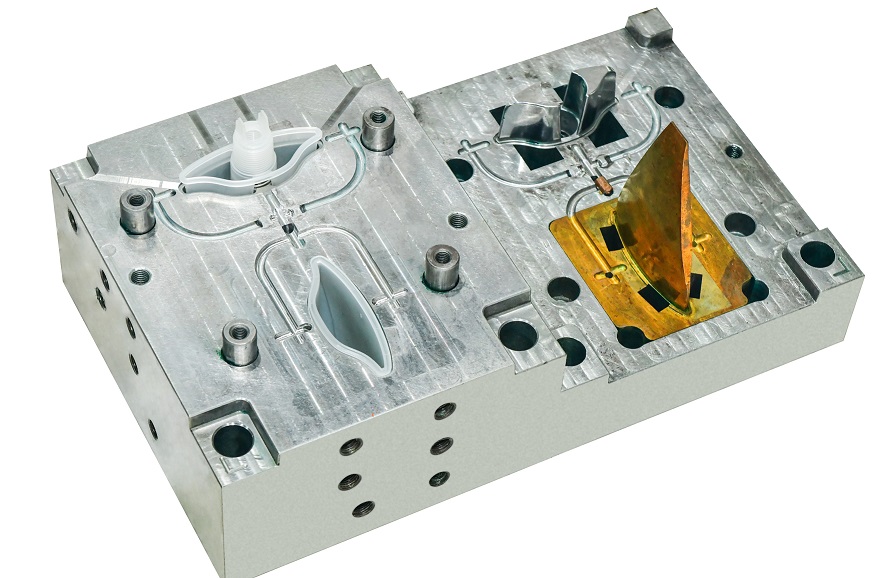

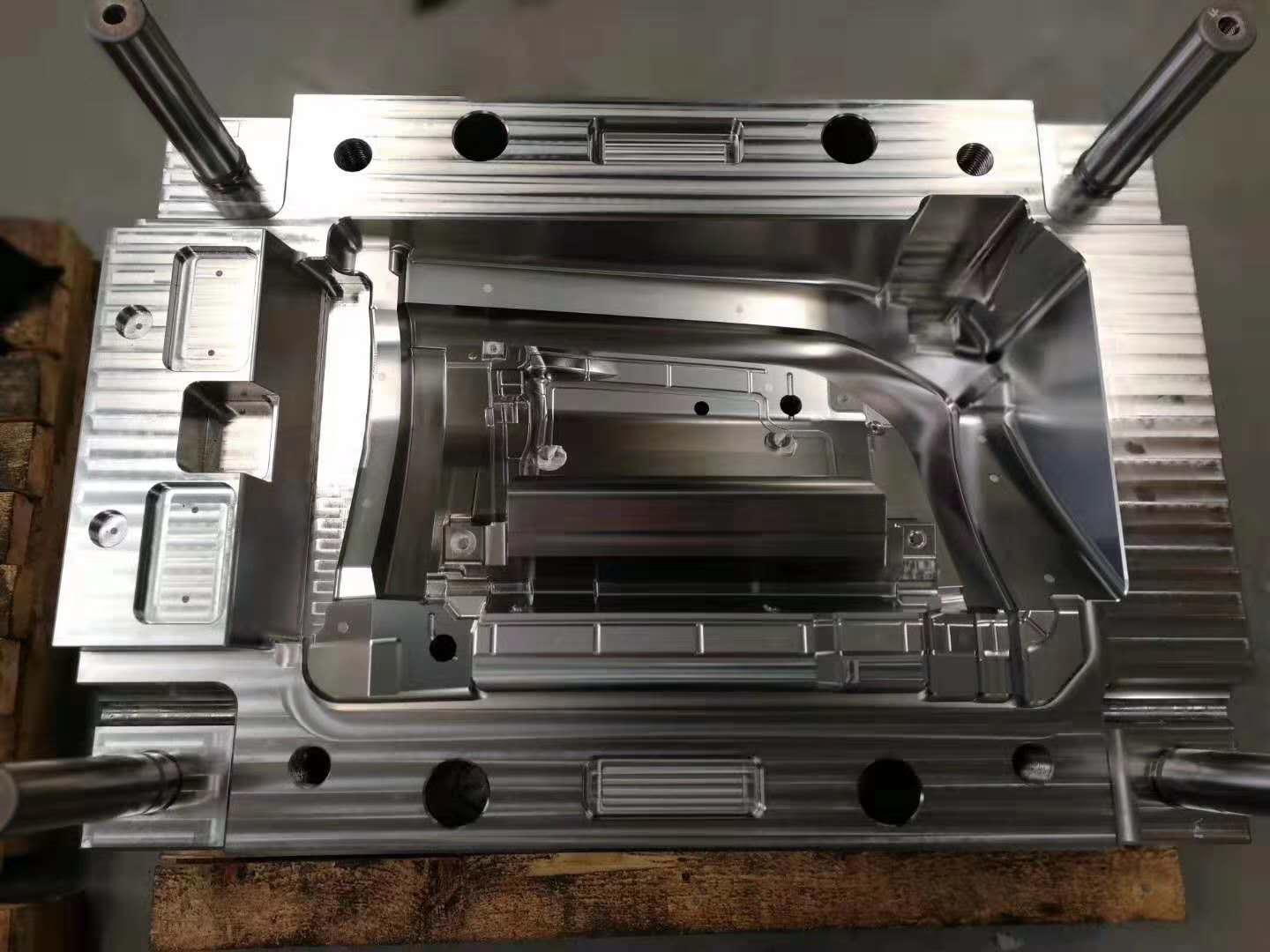

Once an image has been designed, the next step is to design the mold for injection mold manufacturing. Generally the mold is made of steel, aluminium or other metal alloys. Mold design, similar to product design, is another great opportunity to prevent any defects during the custom injection molding process.

This is an image of a mold being developed during its design stage:

The final stage is the manufacturing process. Once a product has been designed, approved by the team and cast, it’s time for the actual manufacturing. This is when the custom injection molding plastic is heated and poured into the plastic injection mold, by way of a custom injection molding machine. Once cooled the mold is opened and the part ejected. Any excess is sheared off automatically and manually removed. This cycle can repeat, even hundreds of thousands of times in only just a short space of time.

For such a complex process the whole undertaking is both impressive and swift. It’s no wonder such a thing is the go-to for creating custom injection molding parts.

How Much Does Custom Injection Molding Cost?

That depends. I’m sure that’s not a very satisfying answer but really, it’s possible you’ve seen plenty of custom injection molding services from many custom injection molding companies and they all say the same thing, “Request a quote”. Why? Because there’s no one size fits all philosophy in the way of a custom injection molding cost. There are too many variables, such as the size of the product, its material, the material of the mold itself (for example a steel mold is more expensive but can make significantly more parts than an aluminium one), how many parts do you want to make, how detailed or simple is the design. What about the location of the manufacturer? They too, will expect different price points. With all these variables and much more, is there any surprise the company would like to know more details about your product first in order to better accommodate you and your needs?

Below are some detailed custom plastic injection molded parts made right here at Shineyuu:

What Custom Injection Molding Companies Are Right For Me?

When it comes to custom injection molding manufacturers, choosing the right company is paramount. In order to do so, it helps by understanding what it is you want from the company. Is it quality? Price? Speed? Perhaps a combination of all three. Since Shineyuu is a Chinese custom injection molding company, we beat our competitors on price. Deliver our products from as little as 3 days (depending on design of course) and our quality is unparalleled when it comes to offering a premium custom injection molding service.

In order to quote custom injection molding projects, simply send us an email and we can go from there.

How Shineyuu Does Custom Injection Molding

Custom injection molding can be difficult, and getting the perfect injection mold can feel like an overwhelming task with so much choice on the market – especially considering the complexity of your product and its strict specifications. That is why at Shineyuu we can help ease those concerns. With our exceptional reputation and many years in the industry, we are a leading custom injection molding company and can provide you with a premium custom injection molding service. Regardless of the industry you are in, be it automotive, electronic or a consumer product industry, we can meet your needs for an accurate accurate custom injection molding!

If you enjoyed this article make sure you check out some of the others we have got available, such as 5 Types of Plastic Molding, All About Overmolding and Should I Choose Injection Mold in China.