How is plastic manufactured? Have you ever had an idea in your head that you wanted to build? The next plastic product that could revolutionize the world or even just fatten your wallet that little bit more? It can be a daunting undertaking to build part plastics from scratch however, when you have no idea what needs to be done or undertaken. Fear not, as this article is dedicated towards all the vital steps necessary to fulfilling your next big creation.

If you are looking to create plastic parts for your next project, it is important to get a better understanding of the process, from its initial creation right through to completion. In this sense, we want to provide you with a high-level overview for the creation process of plastic molded parts. So join us in parts 101; where below you will find a step by step guide on how to bring your molded plastic parts into reality!

Create a Design

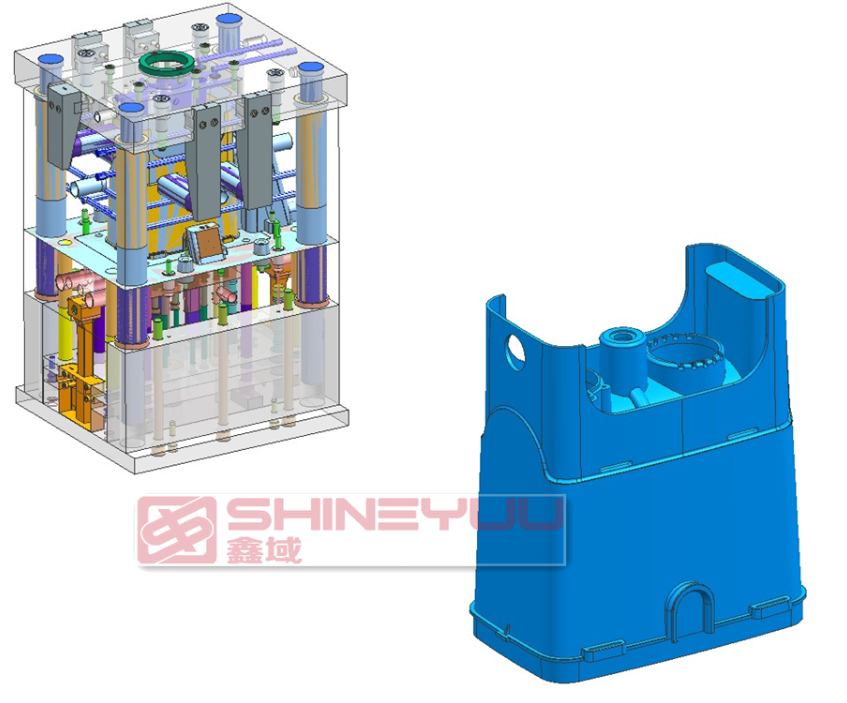

The initial stage of the plastic part process is the design stage. While a part of this process is sketching both 2D and 3D models with a technical team – design engineers and developers, it also includes other factors like considering tolerance requirements, selection of the right materials, manufacturing processes along with the end-use factors in the product which could affect performance (like high temperature environments, weathering and chemicals) and the specific industry which your product would reach (automobile plastic parts might have different safety standards when compared to another industry like food or medical, for example). To see a more in-depth example of this, you can check out our article about the design stage for injection molding, to provide further details.

Here you can see an example of injection molded plastic parts during the design stage.

Select a Manufacturing Process

Another basic principle of manufacturing 101 – how plastic is made. There are several different types of manufacturing processes available when considering plastic parts fabrication. The ones that would be available to you would depend on a variety of factors such as the plastic that has been chosen, costs for affordable parts, cheap plastic molding, quality of finished product, amount of products you would require to be produced and additional factors.

Some like plastic injection molding parts – offer higher quality, mass production and even offering finer details in large and small plastic pieces. But it is also considered a more expensive way of making applications, since it also requires an injection mold part. Another like 3D Printing offers potentially the cheapest way to make plastic parts, however quality suffers and can only be made in small production amounts, usually reserved for making a single prototype before moving onto other means of manufacturing.

Some types of plastic manufacturing are primarily used for specific kinds of products at a cheaper price, like how blow moulding is often used for creating bottles or extrusion moulding is a go-to for making tubes. You can find a detailed explanation of the 5 types of plastic molding here.

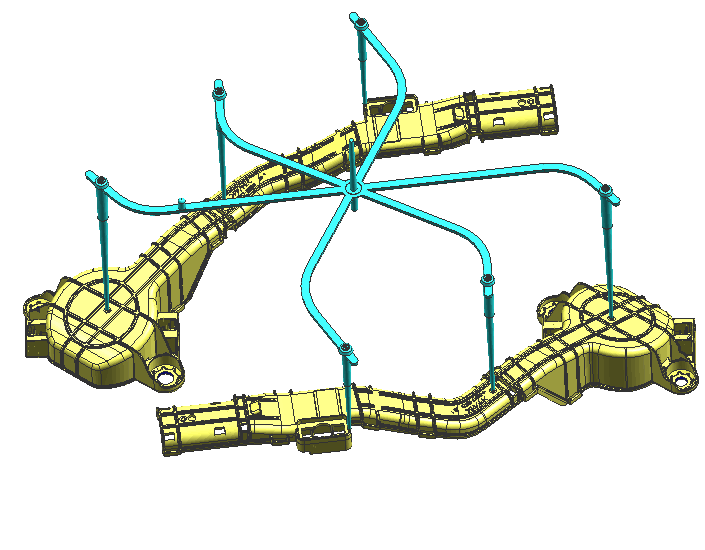

Here you can see some plastic injection mold parts. The melted plastic is injected into the mold, which serves as the template for the finished product.

Choosing the Right Plastic

Not only do you need to select the right manufacturing process for your project, but you will also need to consider the right kind of plastic needed for the product. Choosing a certain manufacturing process will eliminate certain types of plastics that you can use or conversely, choosing the plastic you want to work with first will remove certain types of manufacturing styles available to you.

Why is selecting a plastic important? Essentially, there are a wide variety of plastics on the market and each one comes with a certain set of strengths and weaknesses. Some plastics have a higher melting temperature than others, some are stronger than others, and some give different reactions to chemicals or weathering. Some are better for recycling or some are more toxic than others. Depending on the product you want to make and the market it will be available for it is important to choose the right kind of plastic when moving forward. Take a look at our article The 10 Best Plastic Injection Molding Materials for a list of different possible plastics available or if you want a more detailed explanation of some plastics available you can check out our other articles on plastics here on:

- ABS

- Polycarbonate

- Polyoxymethylene

- Polypropylene

- Low Density Polyethylene

We understand the process of selecting the right plastic materials for your product can be a little daunting at times, which is why if you need our expertise – since we here at Shineyuu are a manufacturing company with many years in the industry – we can provide you with assistance if you simply contact us here and we can help you along every step of the way.

Making plastic parts is no easy feat. There are many factors involved including which plastic to use for your chosen product. Some plastics go well with certain processes, for example ABS is a great plastic that goes with injection molding – which is how the iconic Lego toys are made!

Build a Prototype

A critical step in the custom plastic manufacture process is the prototype stage. This stage is considered the final step before production can begin and is a necessary one, since prototypes are used to reveal problems which can only be seen through real-world applications, taken out of the drawing board and design stage. This allows you to not only hone your design when manufacturing plastic parts, but also to discover better efficiency and functionality of the finished custom plastic pieces.

The plastic parts manufacturer usually offers two primary ways of prototyping; CNC machining, small run injection molding and 3D printing, which when built through the desired materials it can be properly tested to meet all tolerances and cosmetic appearances before the molded parts then proceed to production.

A custom plastic manufacturer will also usually offer some kind of prototyping as an additional service, usually through means of 3D printing or CNC machining.

Production

After the prototyping stage has both refined and vetted your product, it is time to move into production. This can involve either small runs or large runs, but the process to duplicate plastic parts remains largely similar. Plastic parts manufacturers often suggest different types of custom plastics manufacturing depending on the number of your plastic part you would like created. For example, some types of manufacturing – like plastic injection molded parts or rotational moulding can offer faster production speeds when compared to something like 3D Printing when making larger runs (thousands of products), but when making smaller batches this may not be a significant factor.

Ever wonder how to make plastic parts for cars? Here you can see small plastic parts for a car right off the production line, thanks to custom plastic injection molding.

Conclusion

We hope you have found this plastics 101 guide to be useful to you on how to make plastic parts, how is plastic made step by step and better understanding your needs for that next big plastic project undertaking.

We went through the plastic parts manufacturing process, taking us along each step and what needs to be done from creating the initial design, and selecting the correct manufacturing and plastic needed for that design. Then, we suggested what to do at the prototyping stage for your plastic mold parts, followed by the production process and what needs to be monitored at this stage so that your custom plastic product is finalized with as few issues and complications as possible.

We here at Shineyuu understand that there can be all sorts of issues and complications when it comes to creating a new product. In fact, we have spent many years in the game, since we are an injection molding company, plastic mold maker and one of the best custom plastic parts manufacturers on the market. If you are thinking about working on your next plastic parts, and have a wide variety of questions or concerns simply contact us and request a quote, or indeed you can ask us any questions and we will be more than happy to assist you in any way we can!

Be sure to check out our Case Study so that you can see a product taken from its design stage to reality.

If you enjoyed the article make sure you take a look at some of our other posts on many other materials and topics, such as Should I Choose Injection Mold in China, 4 Best Injection Molding Toys and Injection Molding vs 3D Printing for more great information.