Surface finish involves the process of altering a metal’s surface, in the form of reshaping, adding or removing. It is often an essential component of the manufacturing process, since it can completely change the look of a product and significantly improve its aesthetic look and feel.

What is Surface Finish

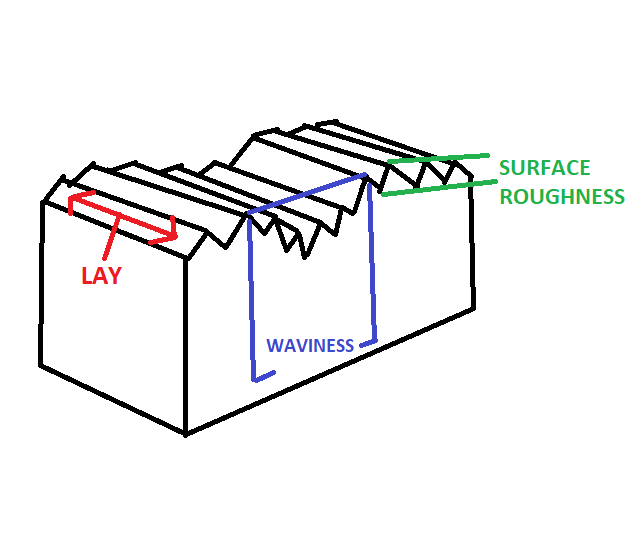

So what exactly is surface finish? Surface finish is generally comprised of three parts: surface roughness, surface waviness and the lay. When one takes into consideration all of these parts then we have a complete manufacturing aspect. Surface roughness refers to the measurement of finely spaced surface irregularities. Usually when machinists talk of surface finish they are often referring to this. Waviness on the other hand, is talking about warped or deflated surfaces. Imagine the peaks and valleys of a wave, its unevenness, and you have a good visual impression when one talks about waviness. Often the cause of this is warping from heating or cooling, or machine defects like that of chatter and deflection. Lay refers to the dominant pattern on the surface and its orientation. Lay is produced by the manufacturing process and can take a variety of patterns, such as: parallel, perpendicular, circular, crosshatched, isotropic, radial and multidirectional.

Below is an image to get a better understanding of the three parts of surface finish:

Why is Surface Finish Important

So why then is surface finish important? Surface roughness itself plays an important part in determining how exactly the finished product interacts with its environment, but also when creating hundreds or thousands of the same part it is important to keep and maintain a level of uniformity throughout all of the products. It would be unusual to have multiple pieces of the same product have a wide variety of rough and smoothness, and would make the product seem lower in quality.

Other reasons surface finish is so important include that it is incredibly important for corrosion and chemical resistant effects, eliminate surface defects, improves electrical conductivity, improves strength of the product and reduces friction effects, as well as adhesion of coatings and paints and generally improves its visual appeal.

Measuring Surface Roughness & Surface Symbols

In order to measure surface roughness we have to calculate the smoothness of a product surface’s profile. This is where we can use a variety of different methods, such as surface roughness charts or using surface finish symbols.

One of the more common machining symbols is that of Ra surface finish. So how do we calculate Ra surface finishes? Ra involves average roughness. This means that we perform a measurement of the average roughness between its highest peaks and the mean line. Although it’s sometimes not enough to define surface roughness, and more specific measurements may be used.

Another of the finishing symbols is that of Rmax. Rmax is the measurement of a vertical distance from the highest peak to the lowest valley, and is mostly best used for anomalies like that of burrs and scratches.

Rz is the average maximum height of the profile. It takes the five largest differences between peaks and valleys, using five sampling lengths. The is the chosen method when more accuracy is needed, as it helps to reduce error, Ra being more sensitive to extremes.

You can see how these are calculated below:

Conclusion

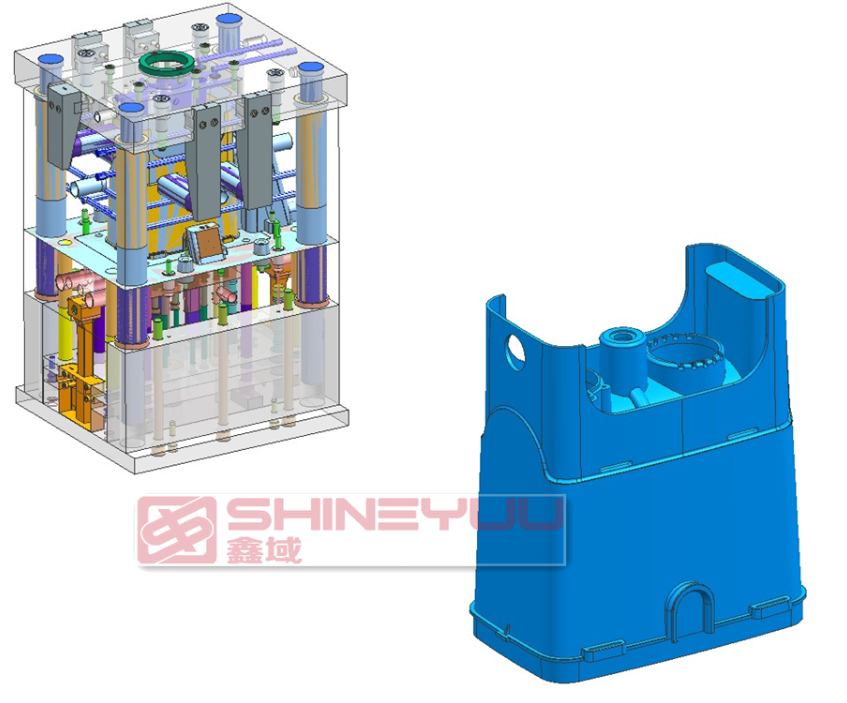

Getting an accurate surface finish can be challenging during the manufacturing process, which is why you should choose us, Shineyuu, who work with rapid tooling and injection molding to help meet your needs. If you need the best prices and the best understanding of the right surface finish for you, simply drop us a line and our team of experts will help meet your surface finishing needs. We offer full dimensional inspection reports along with a wide variety of different finishing processes, like anodizing, electroplating and much more. So contact us today.