So what is overmolding? The overmolding definition is an injection molding process which involves creating a part with two or more plastic materials. It is first injected with a base component, also known as the substrate, which is then given time to harden. These overmolded substrates are often made of plastic. Then the second layer is added, usually the overmolding process takes place with plastic, thermoplastic composite materials or overmolding rubber. Over molding often can be used in a wide range of applications and industries, including automotive, medical, military, overmolding electronics and many more, the reasons for which we will take a look at in further detail below.

Why Would You Overmold

So why exactly would someone choose overmolded plastic over unmolded material? There are a few factors why you may decide overmoulding.

Comfort: One such factor is comfort. Overmolded products often offer an enhanced feel that customers may find more tactile than one without. Take for example overmolded rubber on a plastic toothbrush, without it the toothbrush is still useable, but this extra process enhances its comfort and improves the quality of the product in the consumer’s eyes.

Visual: Speaking of how the consumer views the products, it is also a great enhancer of a products visible appeal. It helps a product to stand out on the shelf, by using multiple colored plastics it can provide a striking colour contrast. This composite process can even emboss a logo or pattern on a customized substrate.

Cost: In certain industries it can even reduce the cost of spending, since it reduces the number of required parts needed to be added to a product. In the automotive industry for example, it can eliminate the assembly of components for gaskets or bumpers, completely removing secondary finishing operations like priming, painting and coating.

Grip: Others use it for extra grip, improving product performance, perfect for tactile sensitivity like tools or medical products.

The classic Colgate toothbrush uses an over mold design, utilizing both rubber over molding for grip and also for nicer visual appeal:

Materials for Overmolding

There are a wide range of materials available when it comes to choosing an overmold. It’s important however, to be aware of the right materials when deciding on which to choose as different choices can yield different properties when combined. For example, choosing the right plastic for metal overmolding can result in thickness effects or hardness. Rubber overmolding over a plastic product can result in a comfortable grip, like that you can find on a toothbrush. When it comes to injection overmolding there are a wide variety of options available, these include: ABS, HDPE, PEEK, Nylon, PC, PE, PEI, PBTR, PMMA, POM, PP and many more, including other thermoplastic composites.

Overmolding & Insert Molding Differences

While they are similar, overmolding is different to insert molding. Overmolding, as mentioned, involves waiting for the first layer (the substrate made of plastic) to cool first, and then is combined with another overmolding plastic. Insert moulding involves placing an insert – usually metal – into a mold which then has injected plastic flow around it. For insert molding, think of something like a screwdriver, hammer or a USB stick. This encapsulates the metal with a strong single-molded plastic piece, overmolding – although the plastics are joined together – has no such encapsulation.

The handle of the drill utilizes overmolding, while the hammer uses insert molding:

Overmolding vs Insert Molding

When we look at insert molding vs overmolding, it is best to examine both of their strengths and weaknesses.

Insert molded injection has a variety of benefits. Since it eliminates the need for secondary assembly operations, it cuts down on manufacturing times. Because it is used to create one encapsulated mold it is also a great choice for those seeking strong parts that don’t require much assembly, with a larger variety of materials. Insert moulding does have its limitations however, as prototype molding can be a challenge without a corresponding 3D printer for test runs.

Overmolding on the other hand also holds many benefits. Products can be manufactured with multiple materials and colors relatively simply, as mentioned previously this adds extra aesthetic design elements to products not possible otherwise. Overmolding also requires less man-hours and cost when compared to other manufacturing methods, since it does not need to be transferred to other machines to complete its process. For large production runs, or colourfully designed products, overmolding materials is generally a good way to go. However, its upfront costs can be quite high so this means producing a large number of parts to make the costs worthwhile.

Using overmolding techniques can make cars even lighter:

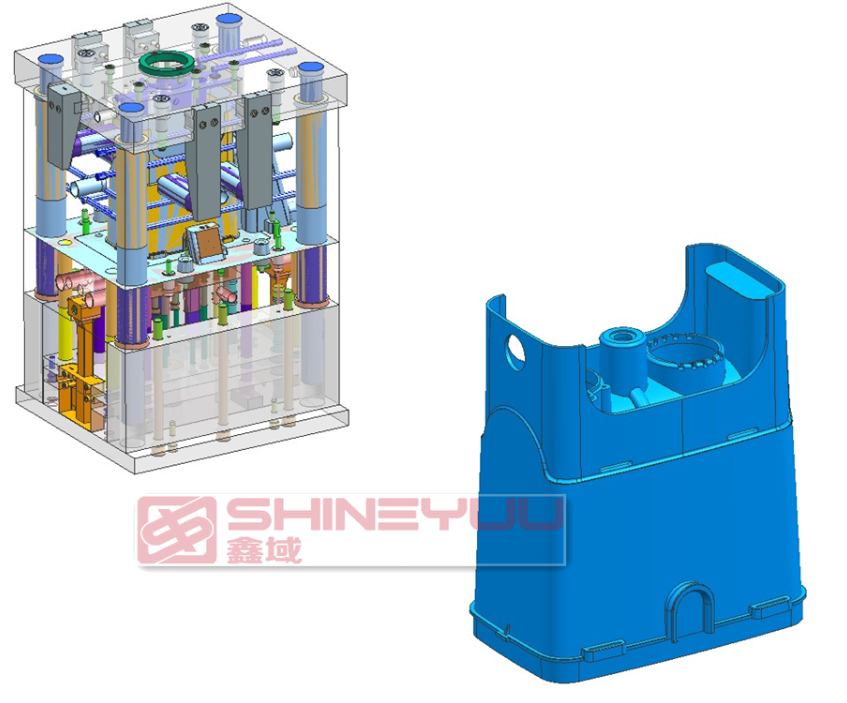

So what are the best scenarios to use one or the other? If your product contains non-plastic parts which are included in the product process then plastic insert molding is the way to go. If however, your product contains multiple types of plastic or polymers then over molding may be the right choice. Although your product may have multiple parts and so it may be difficult to determine which choice to make. Fortunately at Shineyuu, we can help with that, and can help with consultation and bring your product to life. Simply contact us today and we can aid with your product design and build it up with our injection molding processes.

Conclusion

Overmolding is a regular addition to many products. From using silicone overmolding in babies pacifiers to plastic overmolding on a drilling tool, it’s involved in many thermoplastic processes. Perhaps you need it or will consider it for your next project, and that’s where we can help. Also make sure you check out our other articles, like What Exactly is Surface Finish, the 10 Best Plastic Injection Materials, or Custom Injection Molding for more.

We here at Shineyuu are injection molding experts. Overmolding is a core part of what we do. For more information, assisting you with an overmolding design guide or helping you on your next product, simply contact us now to ask any questions or send us a quote today.