What is ABS plastic? ABS stands for Acrylonitrile Butadiene Styrene which is often commonly referred to as ABS. It is both a amorphous polymer and an opaque thermoplastic. A thermoplastic is a plastic that becomes liquefied after it reaches a certain heat temperature. In regards to the ABS melt point it is 210-270°C. If you are wondering is ABS plastic recyclable? Well, instead of burning, ABS will melt and liquefy, so it is ideal for injection molding and because of this reason it can also be easily recycled.

In this article we will take a look at why so many choose ABS as their plastic of choice, including: Is ABS toxic? What are ABS prices? What are some ABS plastic uses including both its strengths and weaknesses.

One of the most famous products of ABS, perhaps of any plastic is Lego. With an estimate that in the course of five decades they have produced over 400 billion Lego blocks!

Advantages of ABS

Acrylonitrile butadiene styrene polymer is regularly chosen for a wide variety of reasons when compared to other plastic materials. ABS thermoplastic possesses a strong resistance to corrosive chemicals and physical impact. Is abs plastic strong? You bet! It is considered to be quite a tough and sturdy plastic, with strong structural strength and stiffness (have you ever tried to break a single piece of Lego before?).

When it comes to ABS plastic costs, it is actually incredibly cost effective and inexpensive; currently ABS price per pound is around $1.50. Not only this, but it is also very easy to machine or create, and when combined with another benefit – the fact that it has a low melting point – make it a very simple choice when used with injection molding or 3D printing. Even those who have their own 3D printers can find it a breeze when using ABS plastic because of the reasons listed above (ABS price and low melting point).

ABS plastic has both a good appearance, can be easily painted and has a smooth surface, making it go to choice for the keys on computer keyboards.

Not only this, but ABS also has great electrical insulation properties, excellent high and low temperature performance and is both easy to paint and glue too!

It is also important to know when wondering is ABS plastic toxic? The answer is no. It is actually one of the safer plastics on the market and because of this it is regularly used in products like children’s toys. It does not possess any known carcinogens nor has there been any severe health defects related to ABS, however it is not used in medical implants or other medical devices.

Disadvantages of ABS

ABS does however have some disadvantages which are important to bear in mind if you are considering using ABS in your next product. It shouldn’t be used under direct sunlight and near open flame, it can become hazardous when burned (below its melting point) producing fumes, does not possess good solvent resistance, limited uses in the food industry and while cheap, it still has a higher price than both polystyrene and polyethylene.

Products of ABS

Because of the strengths and weaknesses listed above, you can find ABS polymers used to create a wide range of products across many industries. Some of these applications include the following:

- Computer keyboard keys

- Lego toys

- Plastic coverings on wall sockets

- Containers

- Power-tool housing

- Automotive parts

- Luggage cases

- Aircraft applications

- Helmets

Many hardhat helmets are made with ABS because of the cost of ABS plastic, its impact resistance and its toughness.

Conclusion

What did we learn about ABS plastic? We learned that it is a low-cost, tough, sturdy plastic with great capabilities in both 3D printing and injection molding manufacturing, used across many industries.

We uncovered several key questions such as what is ABS material, ABS plastic price, we learned what ABS plastic stands for, ABS plastic strength, just some of the acrylonitrile butadiene styrene products it is commonly used in and a host of its strengths and weaknesses.

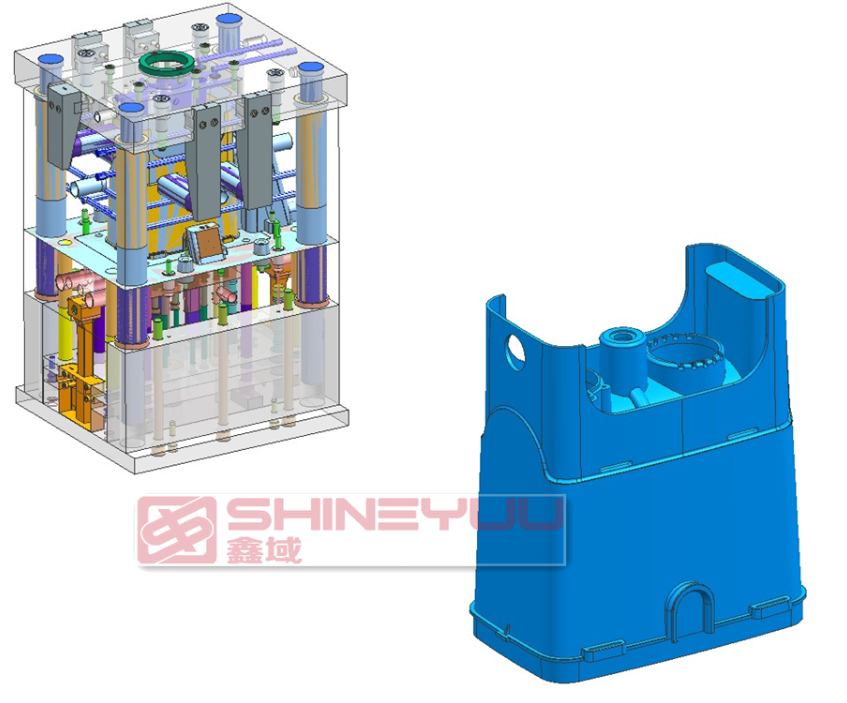

We here at Shineyuu know all about ABS thermoplastics. In fact, we know a lot about all kinds of plastics, since we are an injection molding company! If you are thinking about if your next project should be an ABS product, or are not sure which material is best to use simply contact us and request a quote, or indeed you can ask us any questions and we will be more than happy to assist you in any way we can!

If you enjoyed the article make sure you take a look at some of our other posts on many other materials and topics, such as Need to Know About Polycarbonate, Injection Molding vs 3D Printing and What Exactly is Surface Finish for more great information.