Injection molding is a complex manufacturing process, where material behavior during cooling critically influences final part dimensions. Warpage, defined as the deformation from the intended geometry, arises from several interconnected factors. This analysis delves into the roles of differential shrinkage, geometric variations in ribs and walls, material composition, and thermal gradients, providing a comprehensive understanding for optimizing part accuracy.

Fundamentals of differential shrinkage

Differential shrinkage occurs when different regions of a molded part cool at varying rates or shrink at different magnitudes because of their specific material or geometric properties. This phenomenon induces internal residual stresses that manifest as warpage upon ejection. Key aspects include:

Material thermal properties. The coefficient of thermal expansion and shrinkage rate influence stress development. Unfilled polymers often exhibit higher shrinkage compared to fiber-reinforced composites.

Fiber orientation and distribution. In fiber-filled materials, anisotropic properties mean shrinkage varies with fiber alignment, often reducing overall shrinkage but introducing directional warping if fibers are unevenly oriented.

Impact of thickness variations

Wall thickness substantially affects cooling and shrinkage. Thicker sections experience slower cooling, prolonged molecular relaxation, and higher residual stresses, leading to increased warpage. Uniform wall thicknesses promote consistent cooling rates, minimizing internal stress.

Advanced mold design techniques aim to maintain uniform wall thickness or implement gradual transitions to reduce differential shrinkage effects.

Rib geometry — length and thickness

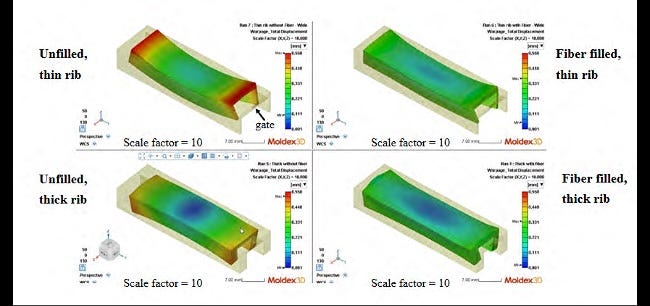

Ribs serve as reinforcement but influence warpage depending on their size.

Thicker ribs — >50% of wall thickness — act as localized heat sinks, delaying cooling and enabling uneven shrinkage. Optimally, ribs should be designed with thicknesses between 30 and 50% of the wall thickness.

Longer ribs — exceeding 20 mm — increase the moment arm for internal stress, amplifying warpage risks. Shorter ribs help contain these effects, especially in thin-walled products.

Finite Element Analysis (FEA) simulations assist in evaluating rib-induced stresses, guiding optimal rib design.

Material selection: Unfilled vs. fiber-filled polymers

Material choice has a profound impact on warpage tendencies.

Unfilled polymers exhibit higher overall shrinkage and lower dimensional stability and, thus, are more prone to warping.

Glass- or carbon-fiber-reinforced polymers are less prone to shrinkage and have improved mechanical stability because of the constrained molecular mobility and anisotropic stiffness. However, fiber orientation must be carefully controlled during molding to prevent directional warpage.

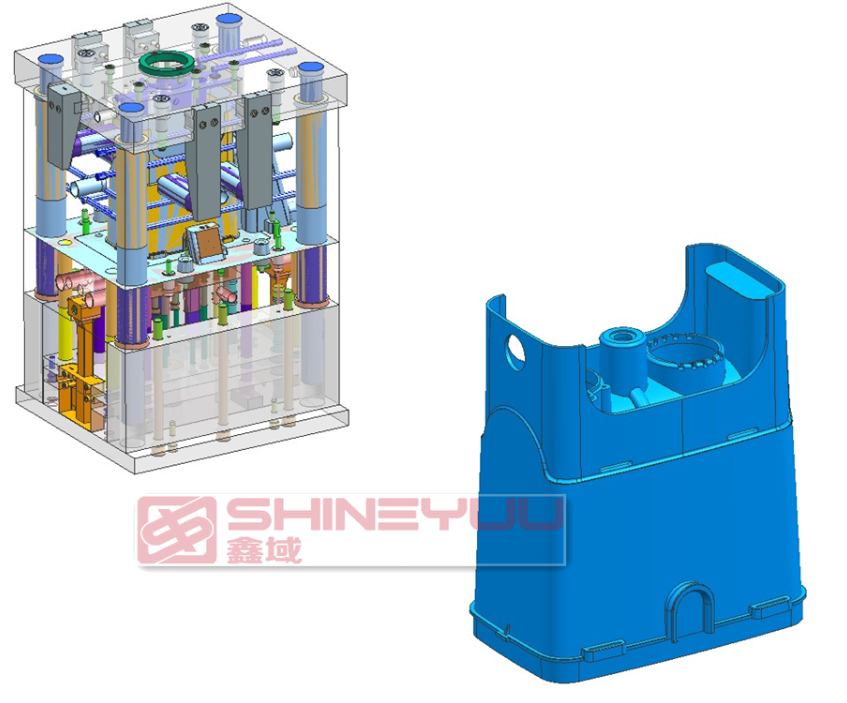

Image courtesy of Moldex3D.

Comparative analysis: Differential shrinkage vs. temperature gradients and fiber orientation

While thermal gradients, such as temperature differentials during cooling, and fiber orientation anisotropy introduce warpage, studies indicate differential shrinkage is typically the dominant factor. Temperature control strategies, such as uniform heating and optimized cooling channels, effectively mitigate thermal stresses. Likewise, controlling fiber orientation through process parameters, such as pack pressure or mold design, can reduce anisotropic warpage.

Design and processing strategies

Effective mitigation of warpage requires the following:

Material optimization. Select low-shrinkage, fiber-filled composites when dimensional stability is critical.

Geometric control. Design for minimal thickness variations, employ uniform rib dimensions, and avoid overly long ribs.

Process parameter tuning. Use simulation software to predict shrinkage patterns, optimize cooling layouts, and control fiber orientation.

Minimizing warpage requires a holistic approach

A holistic approach that considers material properties, geometric features, and process controls is essential for minimizing warpage in injection molded components. Simulation enables engineers to model and predict how these factors interact. A deep understanding of differential shrinkage's dominance enables engineers to fine-tune designs and processing protocols, leading to higher precision, better structural performance, and reduced post-processing costs.